COMMERCIAL STERILIZATION • GENERAL CONCEPTS • DESCRIPTION OF COMMERCIAL STERILIZATION SYSTEMS • HEATING AND COOLING OF FOOD IN A CONTAINER • ESTABLISHMENT OF PROCESS TIMES • INFLUENCE OF COMMERCIAL STERILIZATION ON PRODUCT QUALITY • SUMMARY

COMMERCIAL STERILIZATION • GENERAL CONCEPTS • DESCRIPTION OF COMMERCIAL STERILIZATION SYSTEMS • HEATING AND COOLING OF FOOD IN A CONTAINER • ESTABLISHMENT OF PROCESS TIMES • INFLUENCE OF COMMERCIAL STERILIZATION ON PRODUCT QUALITY • SUMMARY

GENERAL CONCEPTS

GENERAL CONCEPTS

Factors influencing thermal process • product pH or acidity influencing the thermal resistance of the microbial spore. • The heating and cooling characteristics of the product in the container. • The decimal reduction time (D) and the thermal resistance constant (Z) for the microbial population in the product. • The size of the container and the types of heating and cooling media utilized

Factors influencing thermal process • product pH or acidity influencing the thermal resistance of the microbial spore. • The heating and cooling characteristics of the product in the container. • The decimal reduction time (D) and the thermal resistance constant (Z) for the microbial population in the product. • The size of the container and the types of heating and cooling media utilized

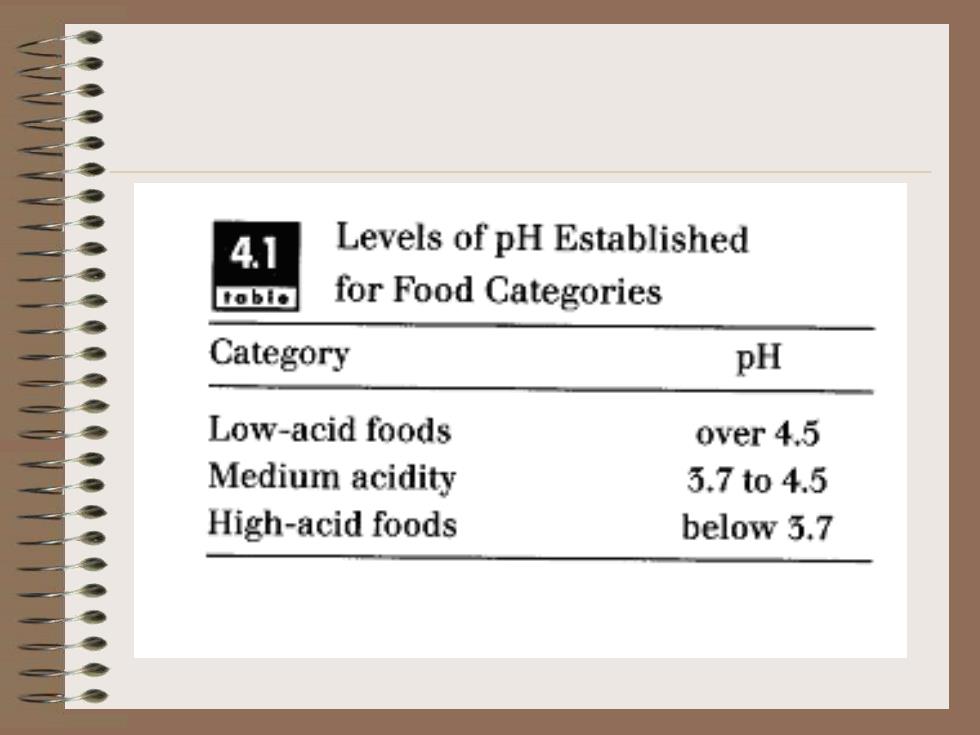

4.1 Levels of pH Established tobie for Food Categories Category pH Low-acid foods over 4.5 Medium acidity 3.7t04.5 High-acid foods below 5.7

• pH below 3.7, thermal process is based on the thermal resistance of microbial spores associated with economic spoilage. • pH over 4.5, thermal processes is based on thermal resistance of spores of microbial pathogens. • pH between 3.7 and 4.5, the processes may be similar to acid foods

• pH below 3.7, thermal process is based on the thermal resistance of microbial spores associated with economic spoilage. • pH over 4.5, thermal processes is based on thermal resistance of spores of microbial pathogens. • pH between 3.7 and 4.5, the processes may be similar to acid foods