Purpose of Pasteurization Processing • Pasteurization is a mild thermal process applied to a liquid food to increase the product shelf life during refrigeration and to destroy vegetative pathogens (brucellosis and tuberculosis), Salmonella and Listeria. • In fruit juice ,to inactivate enzymes

Purpose of Pasteurization Processing • Pasteurization is a mild thermal process applied to a liquid food to increase the product shelf life during refrigeration and to destroy vegetative pathogens (brucellosis and tuberculosis), Salmonella and Listeria. • In fruit juice ,to inactivate enzymes

Purpose of Blanching Processing • In fruits and vegetables to inactivate enzymes. • To removes air from intercellular spaces of a fruit or vegetable • Before canning raw fruits and vegetables and the more severe thermal processes associated with commercial sterilization

Purpose of Blanching Processing • In fruits and vegetables to inactivate enzymes. • To removes air from intercellular spaces of a fruit or vegetable • Before canning raw fruits and vegetables and the more severe thermal processes associated with commercial sterilization

DESCRIPTION OF PROCESSING SYSTEMS • batch-type operation pasteurization • continuous high temperature, short-time (HTST) pasteurization system • rotary hot water system blanching system • Steam blanchers

DESCRIPTION OF PROCESSING SYSTEMS • batch-type operation pasteurization • continuous high temperature, short-time (HTST) pasteurization system • rotary hot water system blanching system • Steam blanchers

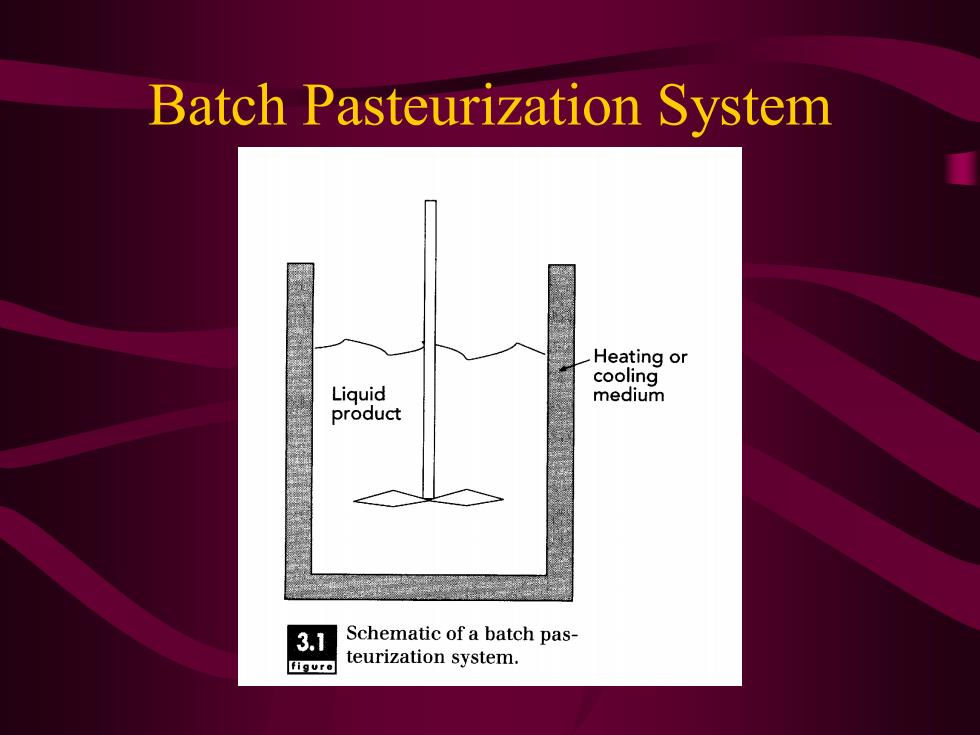

Batch Pasteurization System

Batch Pasteurization System

Batch-type operation • The vessel containing the product has a jacket where a heating medium is introduced. • The liquid product in the vessel is mixed to ensure uniform temperature rise until the desired temperature is reached. • The same jacket is utilized during cooling of the product by introducing a cold medium and cooling the product contact surface

Batch-type operation • The vessel containing the product has a jacket where a heating medium is introduced. • The liquid product in the vessel is mixed to ensure uniform temperature rise until the desired temperature is reached. • The same jacket is utilized during cooling of the product by introducing a cold medium and cooling the product contact surface