CIVL439/WO0D476 Decay in a poorly constructod bullding Reliability and Safety Safety Factors Strength distnbution p Load.Resistance Load.Resistance Safety factors Safety Index B=Safoty Inde Load,Resistance e-Lead 6

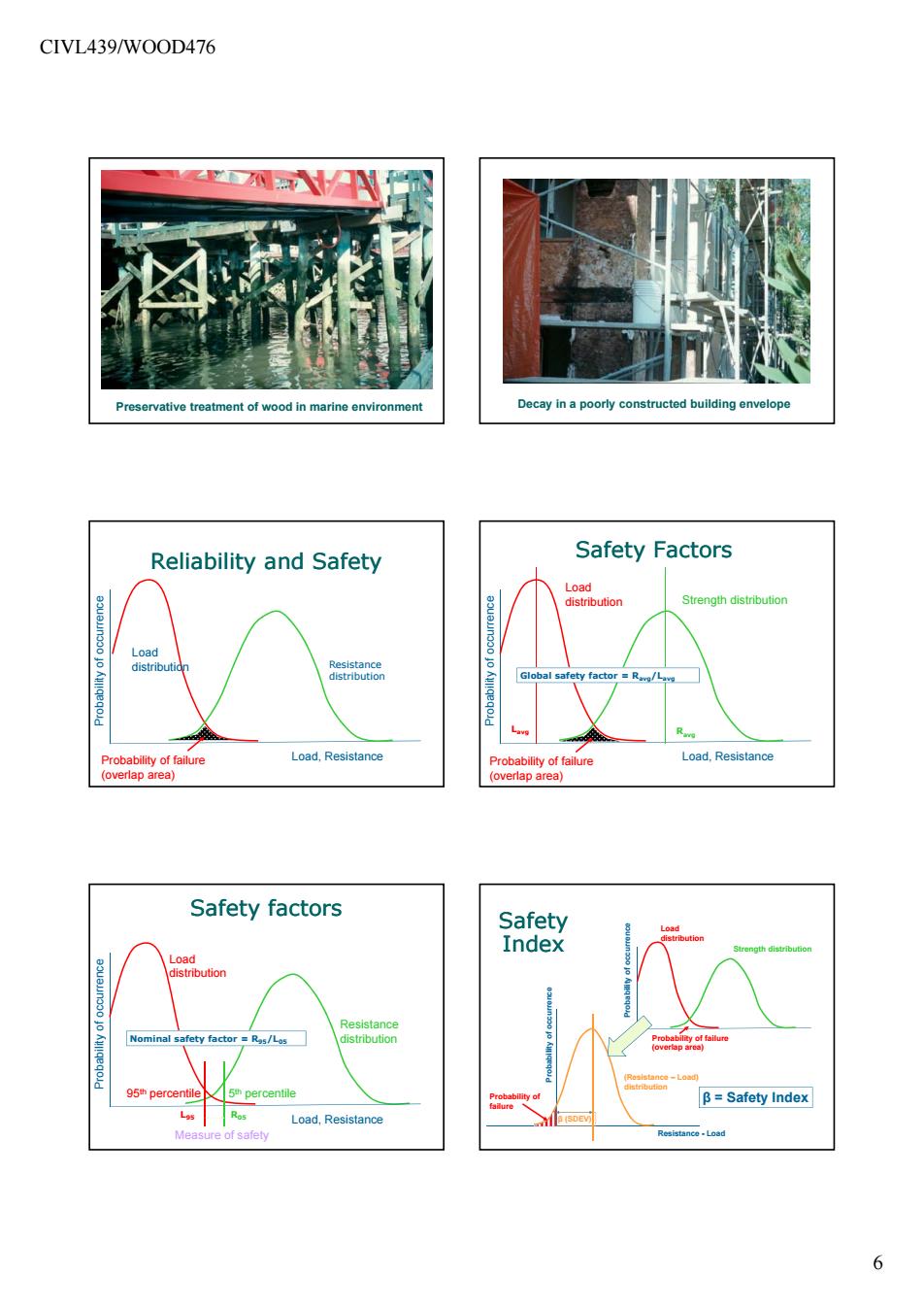

CIVL439/WOOD476 6 Preservative treatment of wood in marine environment Decay in a poorly constructed building envelope Reliability and Safety o Load ccurrence distribution Load, Resistance Probability of o Probability of failure (overlap area) Resistance distribution Safety Factors Load distribution Strength distribution occurrence Load, Resistance Probability of Probability of failure (overlap area) Lavg Ravg Global safety factor = Ravg/Lavg Safety factors Load distribution occurrence Load, Resistance Probability of Measure of safety Resistance distribution 95th percentile 5th percentile Nominal safety factor = R95/L05 L95 R05 Safety Index Load distribution Strength distribution Probability of occurrence currence Resistance - Load Probability of failure (overlap area) Probability of occ (Resistance – Load) distribution β (SDEV) Probability of β = Safety Index failure

CIVL439/W00D476 Reliability Based Design Design equation Factored ActionsFactored Resistance .RELAN software-Dr.R.Foschi(UBC) Resistance (Rs Load (La)Calibration factor Where does the strength of wood come from? Softwood and Hardwood Wood Anatomy Hardwoods Gymnosperms Angiosperms 7

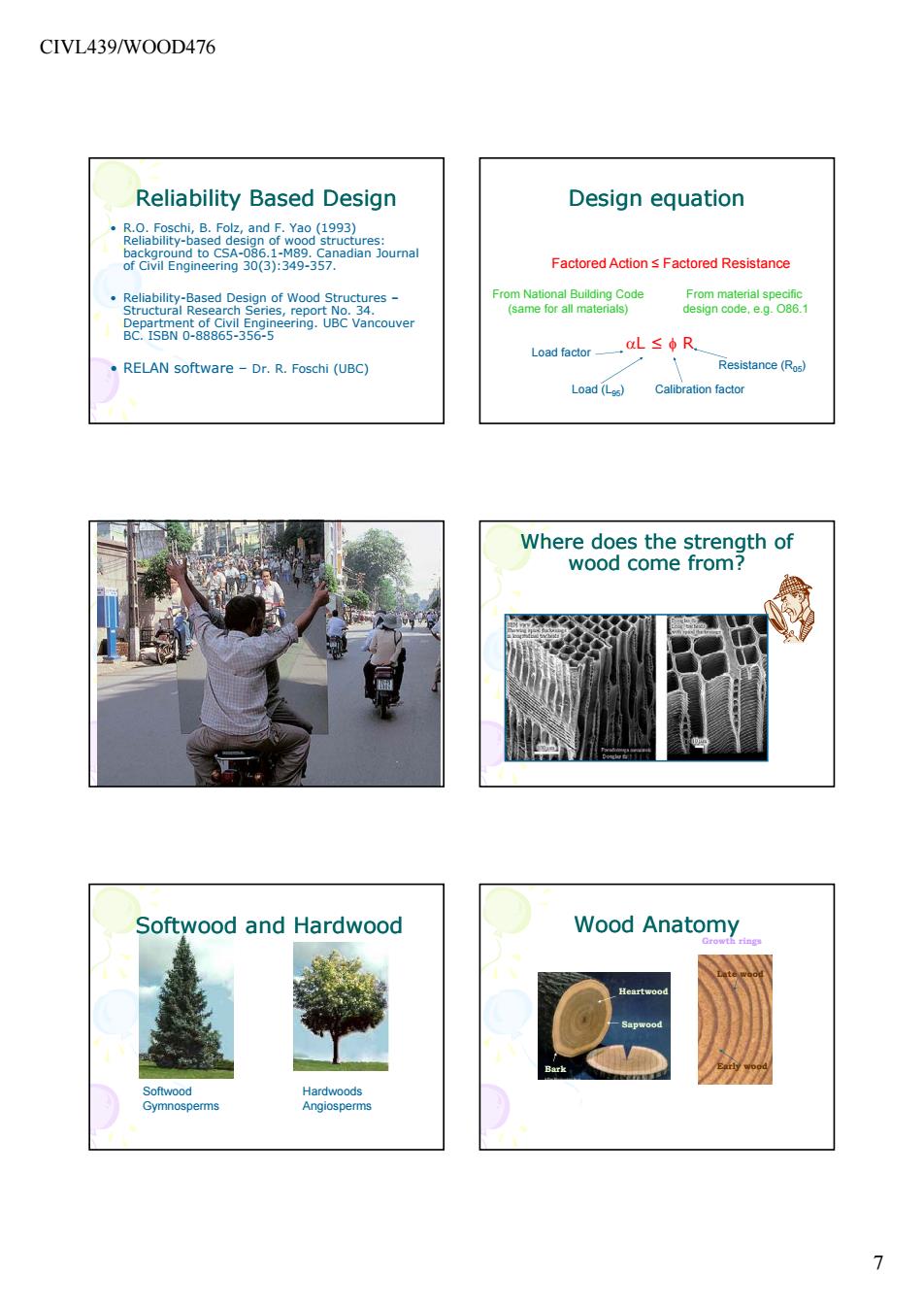

CIVL439/WOOD476 7 Reliability Based Design • R.O. Foschi, B. Folz, and F. Yao (1993) Reliability-based design of wood structures: background to CSA-086.1-M89. Canadian Journal of Civil Engineering 30(3):349-357. • Reliability-Based Design of Wood Structures – Structural Research Series, report No. 34. Department of Civil Engineering. UBC Vancouver BC. ISBN 0-88865-356-5 • RELAN software – Dr. R. Foschi (UBC) Design equation Factored Action ≤ Factored Resistance F N ti l B ildi C d F t i l ifi αL ≤ φ R Load factor Load (L95) Calibration factor Resistance (R05) From National Building Code (same for all materials) From material specific design code, e.g. O86.1 Where does the strength of wood come from? Softwood and Hardwood Softwood Gymnosperms Hardwoods Angiosperms Growth rings Late wood Heartwood Wood Anatomy Early wood Sapwood Bark

CIVL439/WO0D476 Wood Anatomy Cell Wall Cell Wall Structure Drink Straw Analogy -Grain direction. Species and Temperature -Load Duration Directional Elastic Properties of Wood E:E:E,s20:16:1 GuR:Gur:Gar=10:9.4:1 E:G=14:1 8

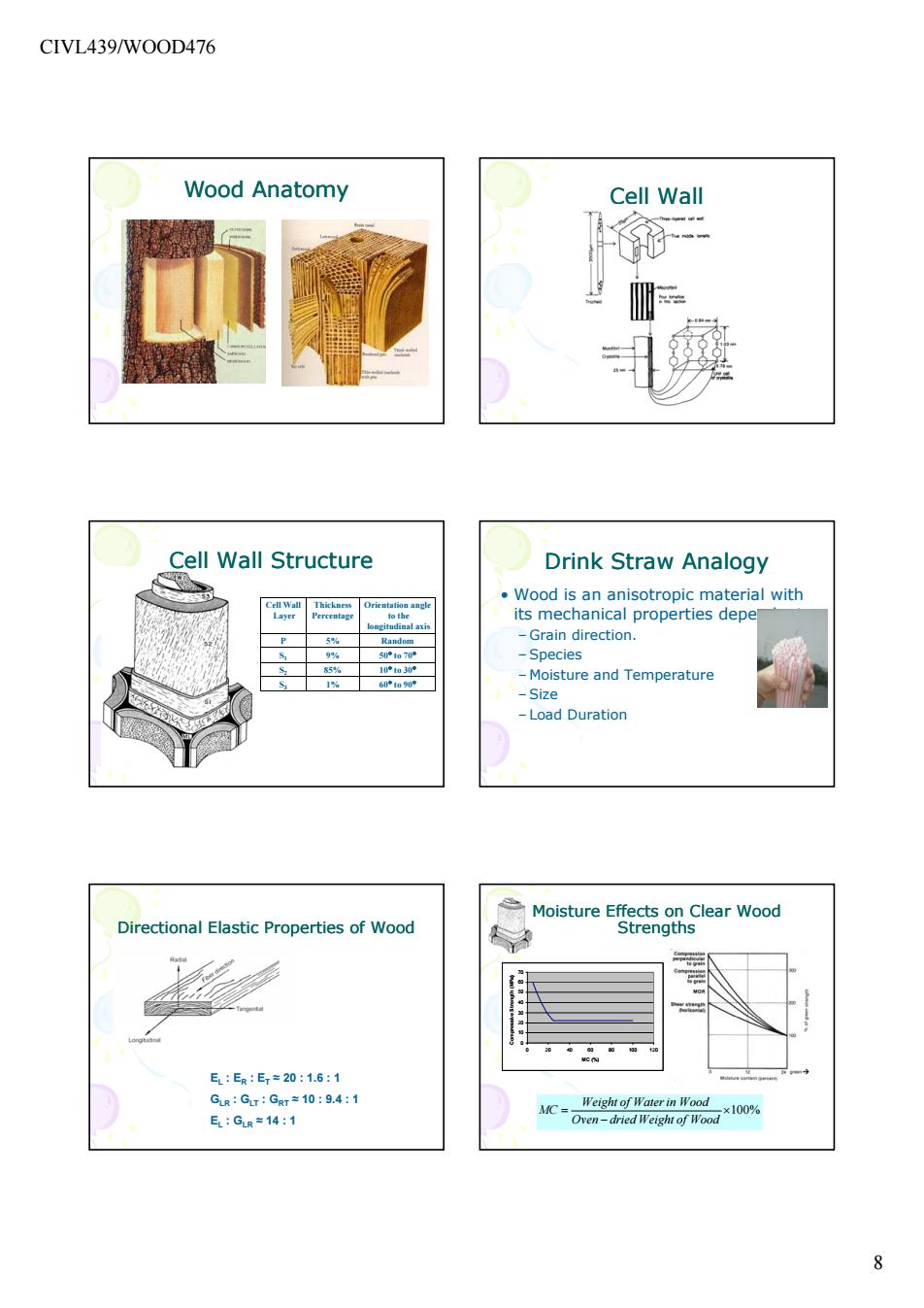

CIVL439/WOOD476 8 Wood Anatomy Cell Wall Cell Wall Layer Thickness Percentage Orientation angle to the longitudinal axis P 5% Random S 9% 50° t 70° Cell Wall Structure S1 9% 50° to 70° S2 85% 10° to 30° S3 1% 60° to 90° Drink Straw Analogy • Wood is an anisotropic material with its mechanical properties dependent – Grain direction. –Species – Moisture and Temperature – Size – Load Duration Directional Elastic Properties of Wood EL : ER : ET ≈ 20 : 1.6 : 1 GLR : GLT : GRT ≈ 10 : 9.4 : 1 EL : GLR ≈ 14 : 1 Moisture Effects on Clear Wood Strengths 30 40 50 60 70 ve Strength (MPa) ×100% − = Oven dried Weight of Wood Weight of Waterin Wood MC 0 10 20 0 20 40 60 80 100 120 MC (%) Compressiv

CIVL439/W00D476 Moisture Variation Induced Stresses Moisture conditions-moist climate Moisture conditions-dry climate 18.9 9

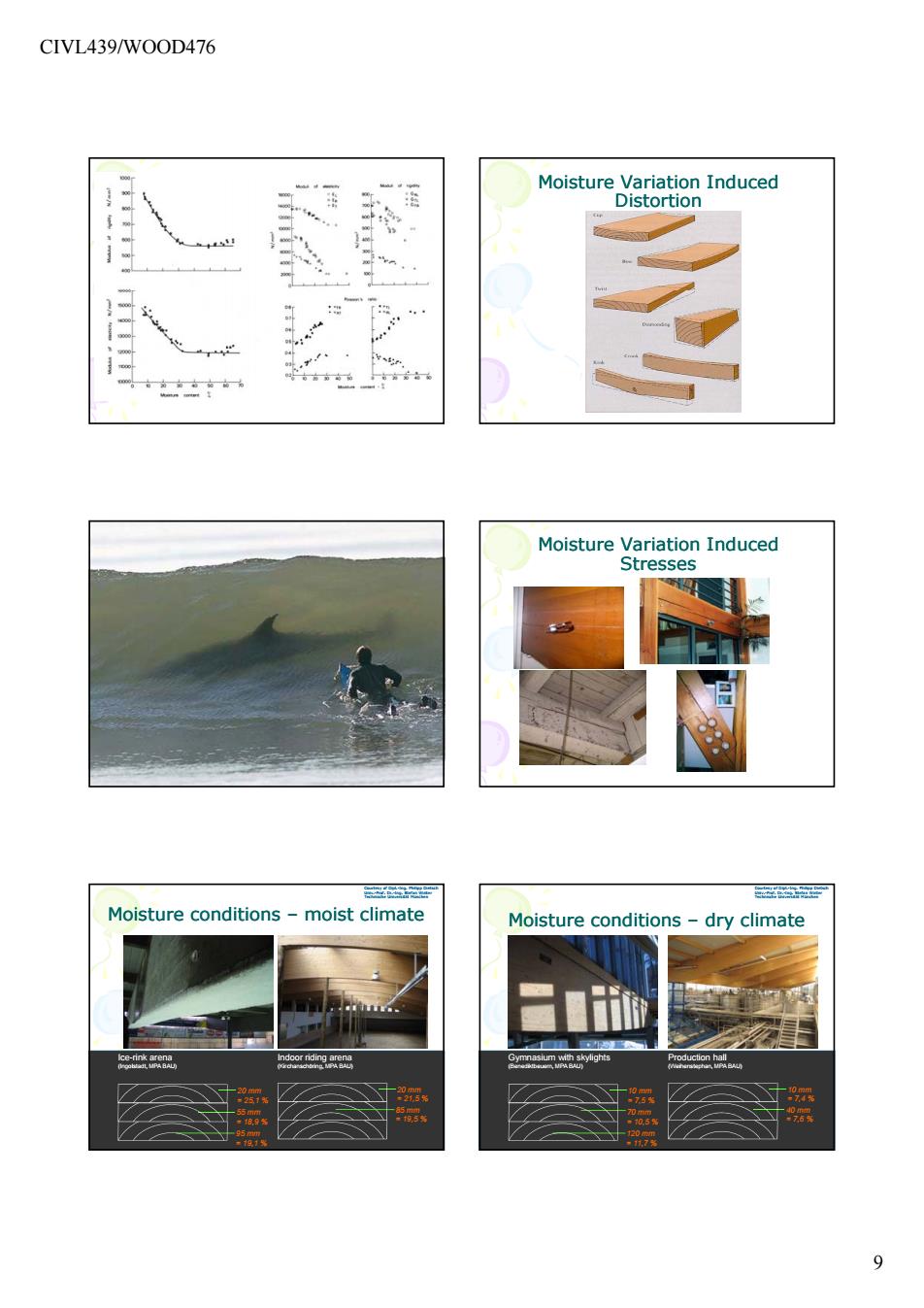

CIVL439/WOOD476 9 Moisture Variation Induced Distortion Moisture Variation Induced Stresses Moisture conditions Moisture conditions – moist climate moist climate Courtesy of Dipl.-Ing. Philipp Dietsch Univ.-Prof. Dr.-Ing. Stefan Winter Technische Universität München Ice-rink arena (Ingolstadt, MPA BAU) Indoor riding arena (Kirchanschöring, MPA BAU) 20 mm = 25,1 % 55 mm = 18,9 % 95 mm = 19,1 % 20 mm = 21,5 % 85 mm = 19,5 % Moisture conditions Moisture conditions – dry climate dry climate Courtesy of Dipl.-Ing. Philipp Dietsch Univ.-Prof. Dr.-Ing. Stefan Winter Technische Universität München Gymnasium with skylights (Benediktbeuern, MPA BAU) Production hall (Weihenstephan, MPA BAU) 10 mm = 7,5 % 70 mm = 10,5 % 120 mm = 11,7 % 10 mm = 7,4 % 40 mm = 7,6 %