Manufacturing and assembling process: Raw materials: L.Aluminum-plastic plate(铝塑板): Specifications:1.5m*1m*0.35cm; Source:purchased parts Used as the raw materials of the box. 2.groups of plastic foldable brackets: Specifications:18cm in length and 6cm in width when folded;50cm in length and 6cm in width when expanded. Source:purchased Used as the brackets(elevator)of the mechanism 3.bolt.shim,nut and the hinge:

Manufacturing and assembling process: Raw materials: 1. Aluminum -plastic plate (铝塑板): Specifications:1.5m*1m*0.35cm; Source:purchased parts Used as the raw materials of the box. 2. groups of plastic foldable brackets: Specifications:18cm in length and 6cm in width when folded;50cm in length and 6cm in width when expanded. Source: purchased Used as the brackets(elevator) of the mechanism 3. bolt,shim,nut and the hinge:

Specifications: M3*10*6 Source:purchased Auxiliary tools(not including the machine tools): Electric saw hot melt glue gun Strong adhesive,pencil and the given tool box. Manufacturing and assembling plan: Based on our product design and the model we have made with UG, we made several plans to manufacture the product and take the one of which we thought to be the most reliable and simplest. As the product we are going to manufacture mainly include 3 parts: the pedestal which we call 'box',the brackets and the holder,we decided

Specifications: M3*10*6 Source: purchased Auxiliary tools(not including the machine tools): Electric saw hot melt glue gun Strong adhesive , pencil and the given tool box. Manufacturing and assembling plan: Based on our product design and the model we have made with UG, we made several plans to manufacture the product and take the one of which we thought to be the most reliable and simplest. As the product we are going to manufacture mainly include 3 parts: the pedestal which we call ‘box’, the brackets and the holder, we decided

to process each part separately and then assemble them For the box,we use the aluminum-plastic plate as the raw material. Cut off the components from the plate using the electric saw according to the size that has been calculated in the design part.Then connect them by strong adhesive and hot melt glue. The brackets purchased need to be reformed,the rotary hinges that connecting the bars are too large in their length,so we decided to replace them by the screws.We need the saw and the fitter machine to be the tools of processing. For the part that holding the mobile phone,we need to slot a groove which is going to be the chute of the prismatic joint that is adjustable for the purpose of expanding and folding the mechanism.Here we will need the lathe for drilling. After all of the procedures above,assemble the separated parts by the screws. Original manufacturing plan: process Auxiliary No materials Requirements process equipments description Model/ Name Code a)According to the assembly required material list, The specifications and none none models are prepare for the actual subject. necessary materials. b)According to

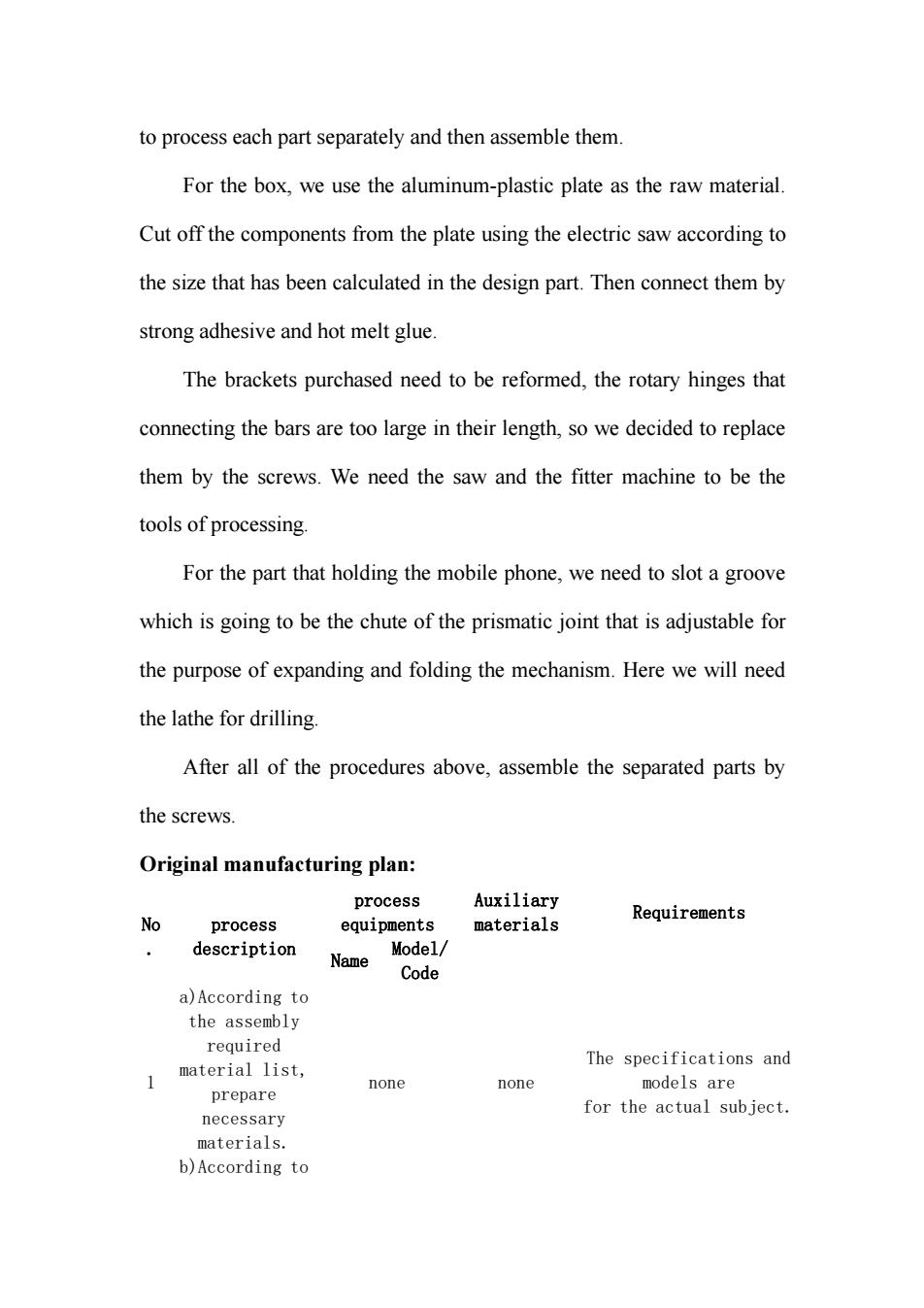

to process each part separately and then assemble them. For the box, we use the aluminum-plastic plate as the raw material. Cut off the components from the plate using the electric saw according to the size that has been calculated in the design part. Then connect them by strong adhesive and hot melt glue. The brackets purchased need to be reformed, the rotary hinges that connecting the bars are too large in their length, so we decided to replace them by the screws. We need the saw and the fitter machine to be the tools of processing. For the part that holding the mobile phone, we need to slot a groove which is going to be the chute of the prismatic joint that is adjustable for the purpose of expanding and folding the mechanism. Here we will need the lathe for drilling. After all of the procedures above, assemble the separated parts by the screws. Original manufacturing plan: No . process description process equipments Auxiliary materials Requirements Name Model/ Code 1 a)According to the assembly required material list, prepare necessary materials. b)According to none none The specifications and models are for the actual subject

the process and auxiliary materials, prepare the machining tools, measuring tools, auxiliary materials. Cutting wood and make it a saw and meet the use 2 sawing sandpapers smooth handling is requirements polishing (锯子和砂 needed and specification 纸) Drilling a)choose the appropriate aperture(选择 合适的孔径) b)aim and make a hole(对准钻 孔) sample c)cut the screw inside the specifications and nut models of the hole screws(车出内 Lathe(车床) 螺纹) should match the screws tap and and nuts duster d)ream the cloth threading using the tap(用丝锥攻 螺纹) e)clear the waste products in the hole(清 理出废物)

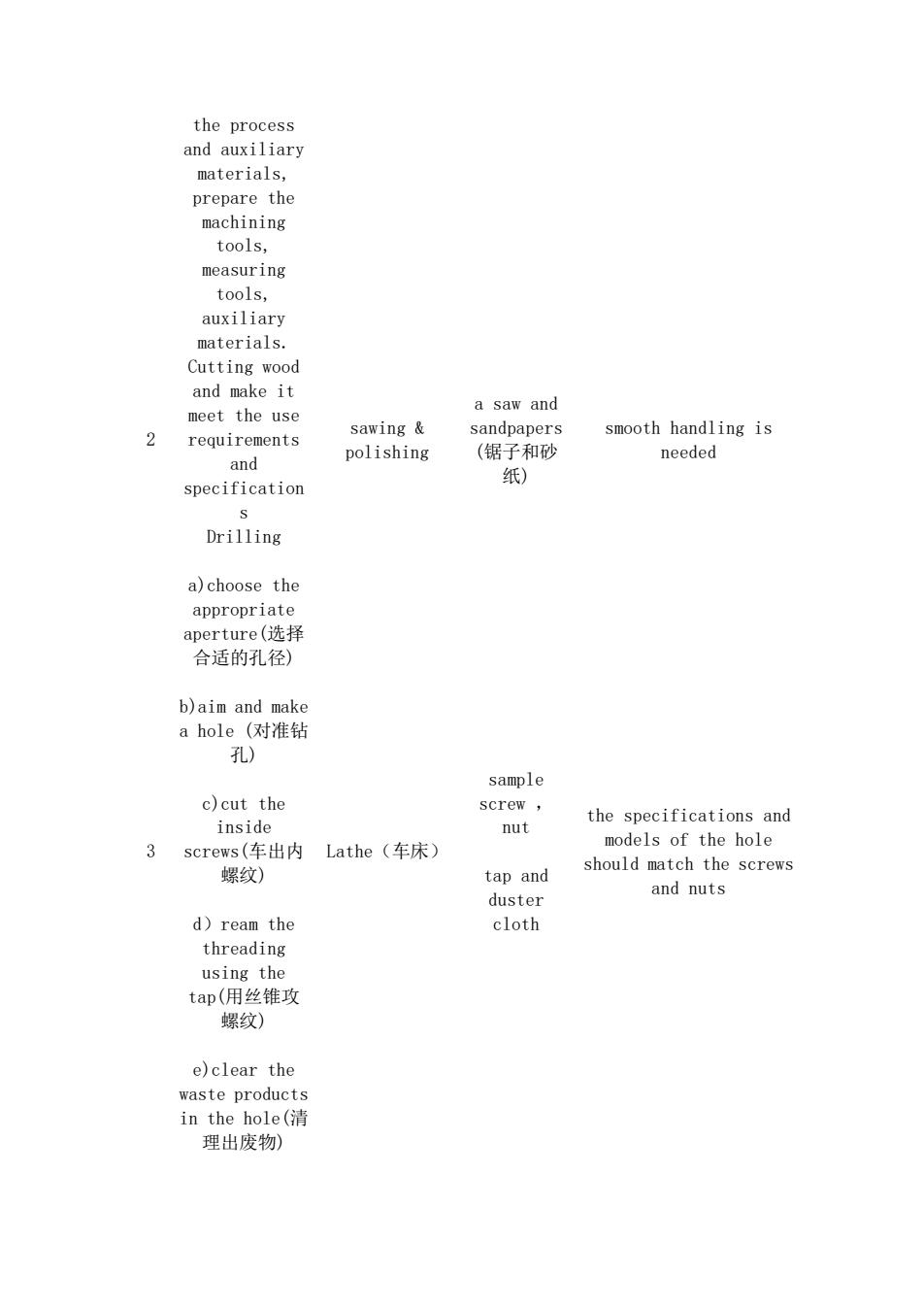

the process and auxiliary materials, prepare the machining tools, measuring tools, auxiliary materials. 2 Cutting wood and make it meet the use requirements and specification s sawing & polishing a saw and sandpapers (锯子和砂 纸) smooth handling is needed 3 Drilling a)choose the appropriate aperture(选择 合适的孔径) b)aim and make a hole (对准钻 孔) c)cut the inside screws(车出内 螺纹) d)ream the threading using the tap(用丝锥攻 螺纹) e)clear the waste products in the hole(清 理出废物) Lathe(车床) sample screw , nut tap and duster cloth the specifications and models of the hole should match the screws and nuts

cutting grooves(键槽) a)fix the Vertical the grooves should meet 4 position,trim Milling File(锉刀) the ming(划线) machine specifications good b)mill using (立式铣床) enough verticle milling machine the screwdrive 5 connecting the r(螺刀) boards /strong adhensive Detailed procedures of manufacturing: 1.Cut off the boards needed from the whole aluminum-plastic plate The parameters of the boards needed:(mm) Size number machining allowance 180*35 #4 machining allowance:5

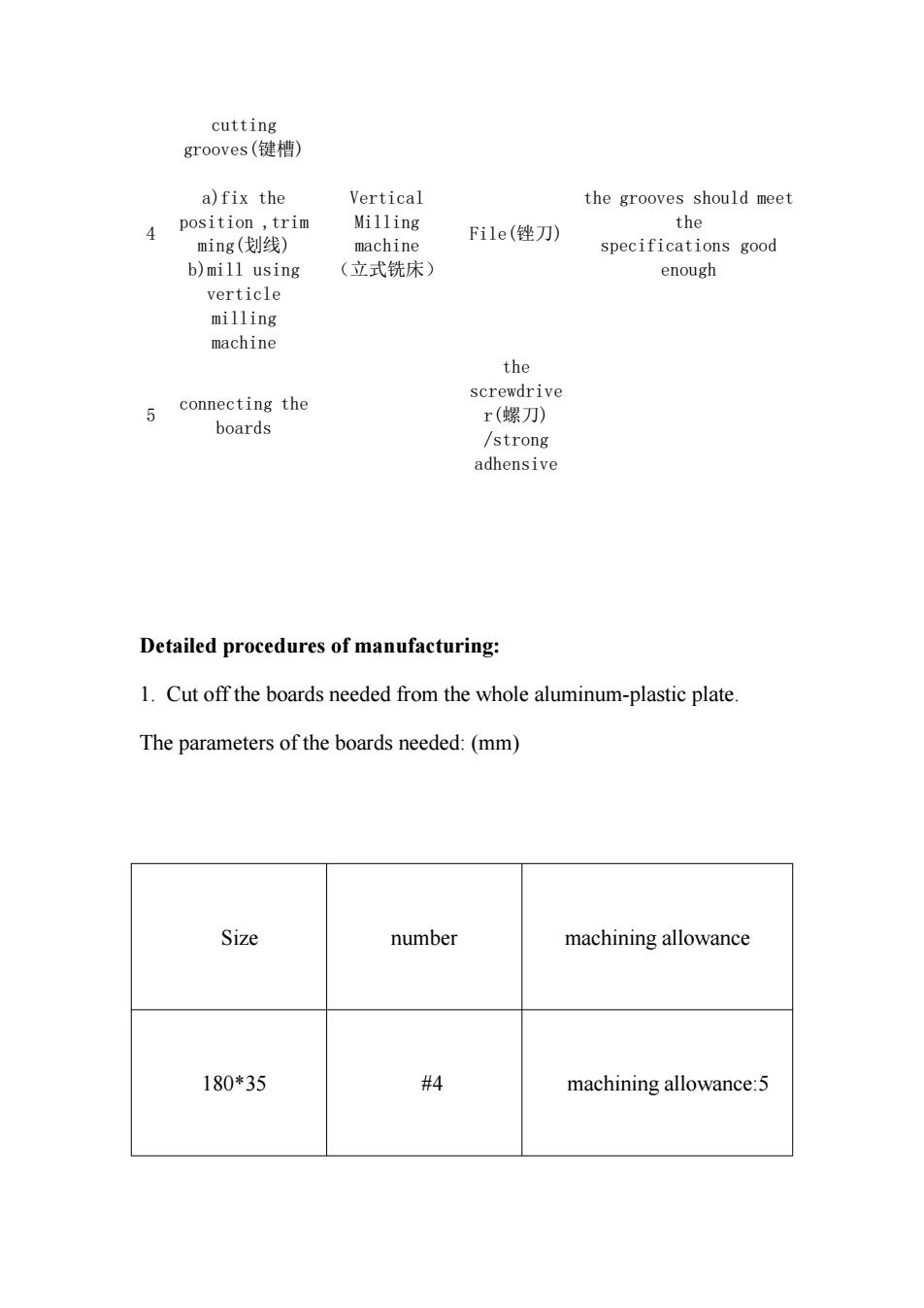

4 cutting grooves(键槽) a)fix the position ,trim ming(划线) b)mill using verticle milling machine Vertical Milling machine (立式铣床) File(锉刀) the grooves should meet the specifications good enough 5 connecting the boards the screwdrive r(螺刀) /strong adhensive Detailed procedures of manufacturing: 1. Cut off the boards needed from the whole aluminum-plastic plate. The parameters of the boards needed: (mm) Size number machining allowance 180*35 #4 machining allowance:5