APPENDIX 1 STRESSES IN THE PLIES OF A LAMINATE OF CARBON/EPOXY LOADED IN ITS PLANE The tables in this appendix give for each ply in the laminate the stresses along the principal orthotropic directions of the ply,denoted as e and t.These stresses are denoted as o,o,,Ta.The laminate is successively subjected to three cases of simple loading: o=1 MPa:normal stress along the 0 direction. o,=1 MPa:normal stress along the 90 direction. Txy=1 MPa:shear stress. CHARACTERISTICS OF EACH PLY V=60%fiber volume fraction. Thickness of each ply:0.13 mm. ■Moduli: Modulus along the fiber direction:E=134,000 MPa. Modulus along the transverse direction:E,7000 MPa. Shear modulus:Ga =4200 MPa. Poisson coefficient:v=0.25. ■ Fracture strength: Tension along the longitudinal direction:nupure=1270 MPa. Compression along the longitudinal direction:pure=1130 MPa. Tension along the transverse direction:,pue=42 MPa. Compression along the transverse direction:o,upure=141 MPa. Shear strength:a nupure=63 MPa. 2003 by CRC Press LLC

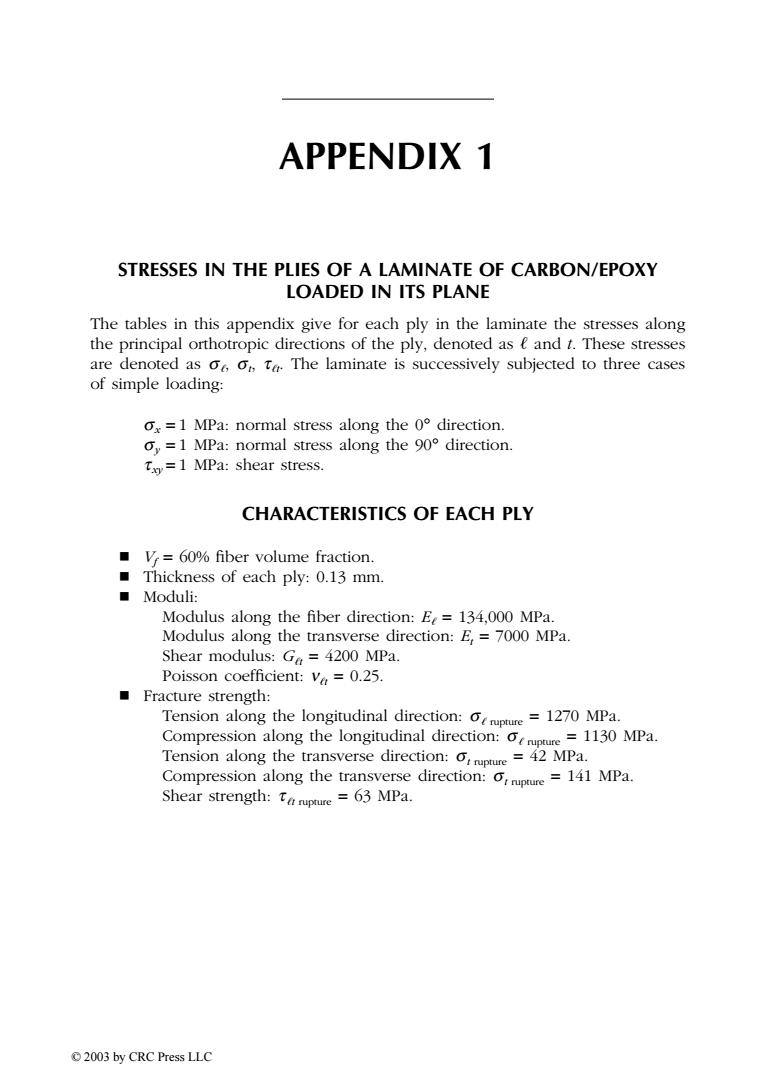

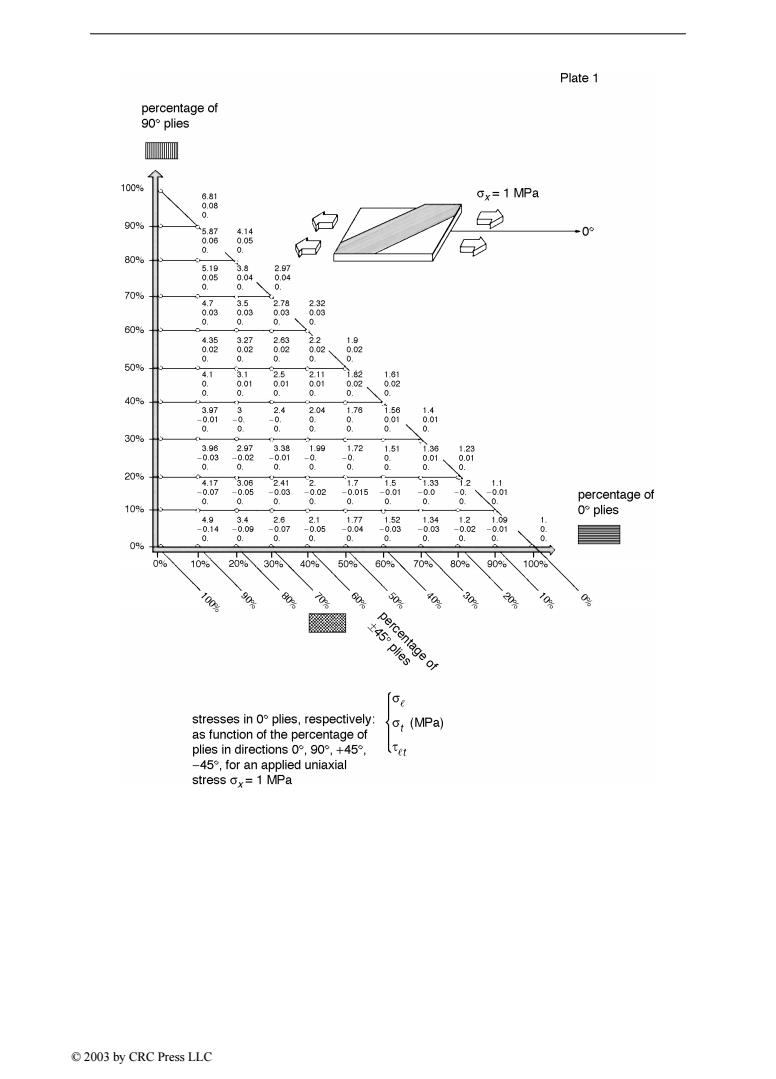

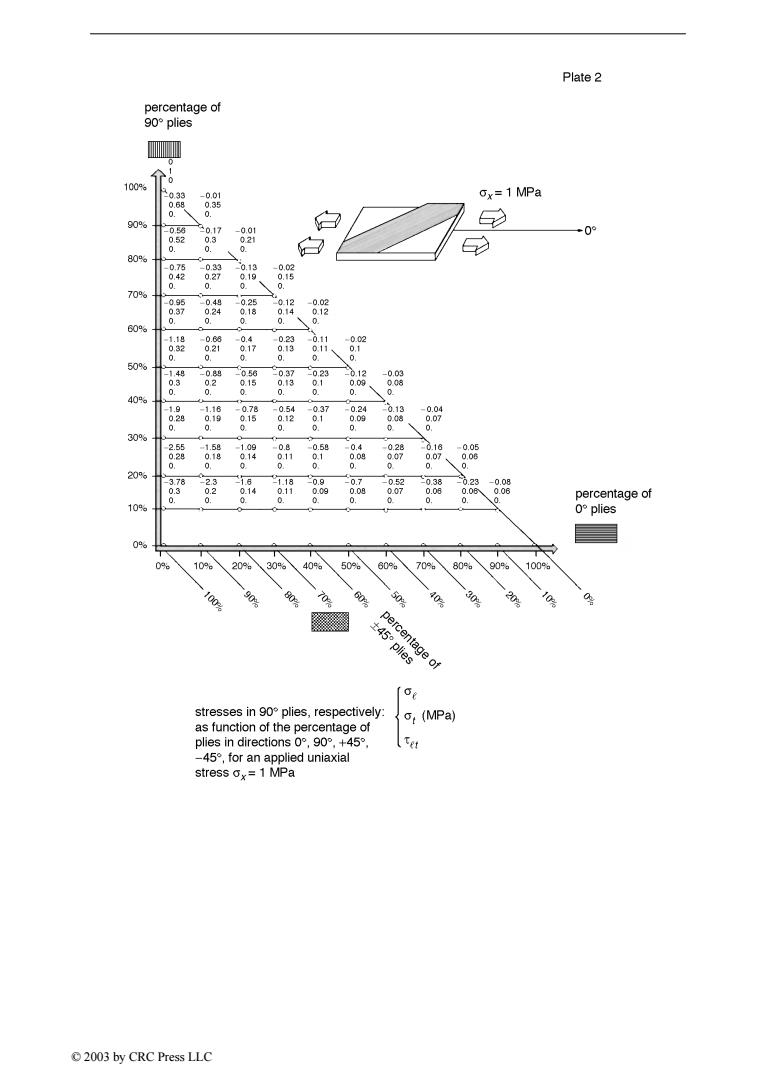

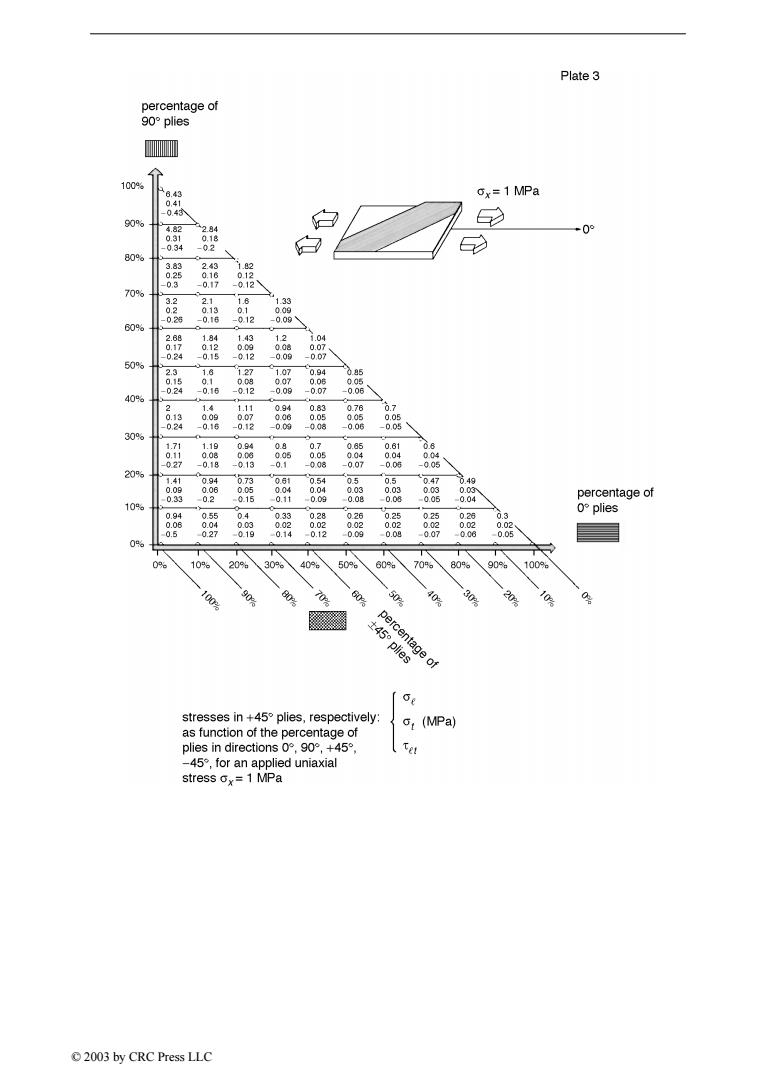

APPENDIX 1 STRESSES IN THE PLIES OF A LAMINATE OF CARBON/EPOXY LOADED IN ITS PLANE The tables in this appendix give for each ply in the laminate the stresses along the principal orthotropic directions of the ply, denoted as and t. These stresses are denoted as σ, σt , τ t . The laminate is successively subjected to three cases of simple loading: σx = 1 MPa: normal stress along the 0° direction. σy = 1 MPa: normal stress along the 90° direction. τ xy = 1 MPa: shear stress. CHARACTERISTICS OF EACH PLY Vf = 60% fiber volume fraction. Thickness of each ply: 0.13 mm. Moduli: Modulus along the fiber direction: E = 134,000 MPa. Modulus along the transverse direction: Et = 7000 MPa. Shear modulus: Gt = 4200 MPa. Poisson coefficient: νt = 0.25. Fracture strength: Tension along the longitudinal direction: σ rupture = 1270 MPa. Compression along the longitudinal direction: σ rupture = 1130 MPa. Tension along the transverse direction: σt rupture = 42 MPa. Compression along the transverse direction: σt rupture = 141 MPa. Shear strength: τ t rupture = 63 MPa. TX846_Frame_Appendix Page 503 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC �������������

Plate 1 percentage of 90°plies 血 100 品 x=1 MPa 90% 白 品 -0 合 2 80% 70% 。 80 品 50% 4.1 品 211 0.02 82 0 0 40 3.97 .78 6 -0.01 0. 8 00 0.01 0 30% 199 72 15到 8 0.01 0 0. 20% 4.17 2.41 1.5 1.33 2 1.1 0.07 -0.03 -0.02 -0.015 -0.01 - 0.01 0 0. o percentage of 10% 0°plies 品2 100 0. 0% 1096 209 309 40e 509 609 70 80% 909 100 00% 90 80 60% 50% 40 30% 20 10 0% percentage of t4 plies (o: stresses in 0 plies,respectively (MPa) as function of the percentage of plies in directions0°,90°,+45 \a -45,for an applied uniaxial stress oy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 504 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 2 percentage of 9o°plies 1009% Ox=1 MPa 90% 2 0 017 -0 82 89 亡 日: 0.25 0.12 -0.02 0.14 0.12 0. 0 8数 0.11 50%6 149 -0.37 0.23 -0.12 -0.03 015 0.13 01 .09 0.08 0. 0. 0 0. 0 a19 -0.54 -0.37 -0.24 0.13 0.04 0.12 0.09 008 .07 0. 0. 0 0 0 0 0 30% 89 88 0 20% 1.6 1.18 0.9 -0.7 -0.52 0.38 -0.23 -0.08 14 0.11 .09 0.08 .07 0.0 0.08 0.06 10 0. 0. 0 0 0 0 percentage of 0°plies 0%e 0% 10 209 30% 4096 50% 60% 70% 809% 90 100 100% 90% 80% 70 60% 50% 30% 20% 10% percentage of ±45°plies 6 stresses in 90 plies,respectively: (MPa) as function of the percentage of plies in directions0°,9o°,+45°, -45°,for an applied uniaxial stress ox=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 505 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

Plate 3 percentage of 90°plies 1009 6.43 Ox=1 MPa 0.41 0.4③ 90% 2.84 白 -0 0.18 -0.34 -02 2.43 1.82 0.16 0.12 0.17 -0.12 2.1 0.13 733 0.09 -0.28 -012 -0.09 889 品8 .04 0.07 0.15 0.09 0.07 -0.16 0.06 品 8 0.7 1小幼 8d 8 0.7 0.85 0.61 0.05 0.04 0.04 004 013 008 -0.07 0.05 0.05 673 0 0.54 05 0.5 0.47 9 0.05 0.04 0.04 0.03 0.03 0.03 0.2 0.15 percentage of 0.11 -0.09 0.08 0.08 0.05 -0.04 0°plies 82 88 0% 0% 10% 20阳 30% 409% 509% 709 809 90% 1009 100% 90 80r 60% 40% 30% 20% percentage ±45°pies 6 stresses in +45 plies,respectively (MPa) as function of the percentage of plies in directions0°,90°,+45° 人心 -45°,for an applied uniaxial stress cy=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 506 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC

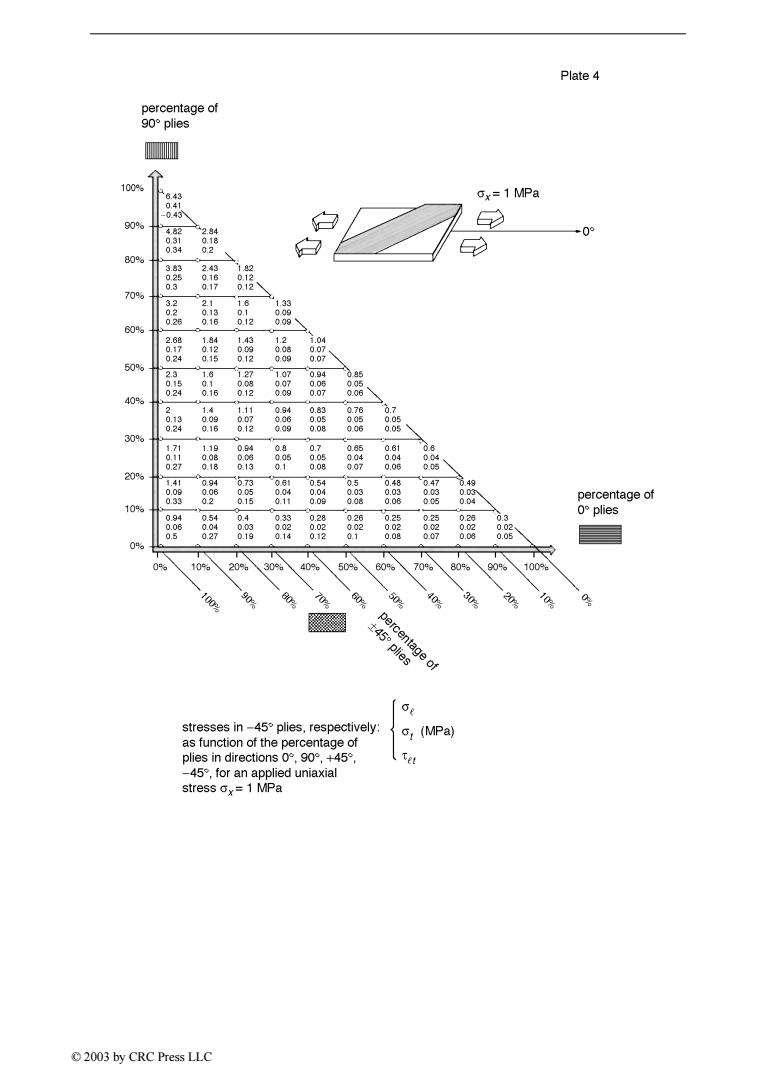

Plate 4 percentage of 9o°plies 1009 x=1 MPa 白 -09 宁 甜 品2 品 品。 8 88 0.7 0.05 0.08 8 0.05 鹏 8 88 0.54 0. 0.48 047 88s 88 0.03 0.03 0.06 003 0.15 0.04 percentage of 888 0.4 8 0.28 9 0.25 025 0.25 0°plies 03 0.03 0.02 0.02 0.02 0.02 0.02 0. 0.27 0.19 0.14 0.12 0.1 0.0g 0.07 0.08 0.05 0 0% 10 209 30%a 40% 50% 60% 709% 80% 90% 100% 00% 90 80r% 60% 50% 0% 30% 20% 0 percentage of t4 plies 6 stresses in-45 plies,respectively: G:(MPa) as function of the percentage of plies in directions0°,90°,+45 -45°,for an applied uniaxial stress cx=1 MPa 2003 by CRC Press LLC

TX846_Frame_Appendix Page 507 Thursday, July 11, 2002 5:42 PM © 2003 by CRC Press LLC