This book addresses the issue of designing the microstructure of fiber composite materials in order to obtain optimum perfor- mance.Besides the systematic treatment of conventional con- tinuous and discontinuous fiber composites,the book also presents the state-of-the-art of the development of textile structural com- posites as well as the nonlinear elastic finite deformation theory of flexible composites. The author's experience during twenty years of research and teaching on composite materials is reflected in the broad spectrum of topics covered,including laminated composites,statistical strength theories of continuous fiber composites,short fiber composites,hybrid composites,two-and three-dimensional textile structural composites and flexible composites.This book provides the first comprehensive analysis and modeling of the thermo- mechanical behavior of fiber composites with these distinct micro- structures.Overall,the inter-relationships among the processing, microstructures and properties of these materials are emphasized throughout the book. The book is intended as a text for graduate or advanced undergraduate students,but will also be an excellent reference for all materials scientists and engineers who are researching or working with these materials

This book addresses the issue of designing the microstructure of fiber composite materials in order to obtain optimum perfor- mance. Besides the systematic treatment of conventional con- tinuous and discontinuous fiber composites, the book also presents the state-of-the-art of the development of textile structural com- posites as well as the nonlinear elastic finite deformation theory of flexible composites. The author's experience during twenty years of research and teaching on composite materials is reflected in the broad spectrum of topics covered, including laminated composites, statistical strength theories of continuous fiber composites, short fiber composites, hybrid composites, two- and three-dimensional textile structural composites and flexible composites. This book provides the first comprehensive analysis and modeling of the thermo- mechanical behavior of fiber composites with these distinct micro- structures. Overall, the inter-relationships among the processing, microstructures and properties of these materials are emphasized throughout the book. The book is intended as a text for graduate or advanced undergraduate students, but will also be an excellent reference for all materials scientists and engineers who are researching or working with these materials

TSU-WEI CHOU Jerzy L.Nowinski Professor of Mechanical Engineering University of Delaware Microstructural design of fiber composites The righr of the Lainrsityo时Cambridge lu print anu yel The Uaivernly har prinred ad pubfished romtinousfy e1584. CAMBRIDGE UNIVERSITY PRESS Cambridge New York Port Chester Melbourne Sydney

TSU-WEI CHOU Jerzy L. Nowinski Professor of Mechanical Engineering University of Delaware Microstructural design of fiber composites The right of the University of Cambridge to print and sell »m granted by Henry VIII in 1534. and published continuousl since 1584. CAMBRIDGE UNIVERSITY PRESS Cambridge New York Port Chester Melbourne Sydney

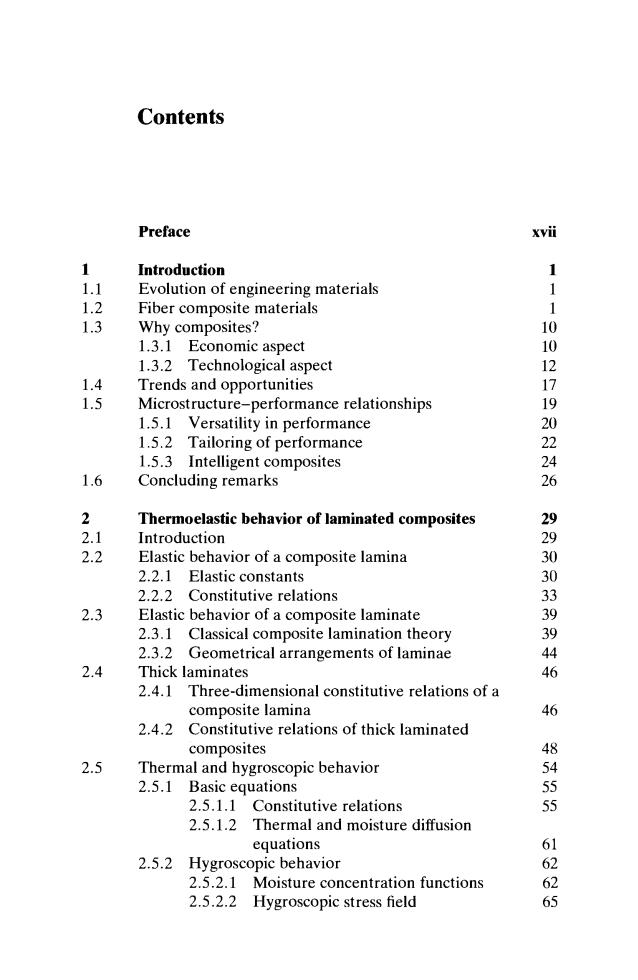

Contents Preface xvii 1 Introduction 1 1.1 Evolution of engineering materials 1 1.2 Fiber composite materials 1 1.3 Why composites? 10 1.3.1 Economic aspect 10 1.3.2 Technological aspect 12 1.4 Trends and opportunities 17 1.5 Microstructure-performance relationships 19 1.5.1 Versatility in performance 20 1.5.2 Tailoring of performance 22 1.5.3 Intelligent composites 1.6 Concluding remarks 26 2 Thermoelastic behavior of laminated composites 29 2.1 Introduction 29 2.2 Elastic behavior of a composite lamina 30 2.2.1 Elastic constants 30 2.2.2 Constitutive relations 33 2.3 Elastic behavior of a composite laminate 39 2.3.1 Classical composite lamination theory 39 2.3.2 Geometrical arrangements of laminae 44 2.4 Thick laminates 46 2.4.1 Three-dimensional constitutive relations of a composite lamina 46 2.4.2 Constitutive relations of thick laminated composites 48 2.5 Thermal and hygroscopic behavior 54 2.5.1 Basic equations 55 2.5.1.1 Constitutive relations 55 2.5.1.2 Thermal and moisture diffusion equations 61 2.5.2 Hygroscopic behavior 62 2.5.2.1 Moisture concentration functions 62 2.5.2.2 Hygroscopic stress field 65

Contents Preface xvii 1 1.1 1.2 1.3 1.4 1.5 1.6 2 2.1 2.2 2.3 2.4 Introduction Evolution of engineering materials Fiber composite materials Why composites? 1.3.1 Economic aspect 1.3.2 Technological aspect Trends and opportunities Microstructure-performance relationships 1.5.1 Versatility in performance 1.5.2 Tailoring of performance 1.5.3 Intelligent composites Concluding remarks Thermoelastic behavior of laminated composites Introduction Elastic behavior of a composite lamina 2.2.1 Elastic constants 2.2.2 Constitutive relations Elastic behavior of a composite laminate 2.3.1 Classical composite lamination theory 2.3.2 Geometrical arrangements of laminae Thick laminates 1 1 1 10 10 12 17 19 20 22 24 26 29 29 30 30 33 39 39 44 46 2.4.1 Three-dimensional constitutive relations of a composite lamina 46 2.4.2 Constitutive relations of thick laminated composites 48 2.5 Thermal and hygroscopic behavior 54 2.5.1 Basic equations 55 2.5.1.1 Constitutive relations 55 2.5.1.2 Thermal and moisture diffusion equations 61 2.5.2 Hygroscopic behavior 62 2.5.2.1 Moisture concentration functions 62 2.5.2.2 Hygroscopic stress field 65

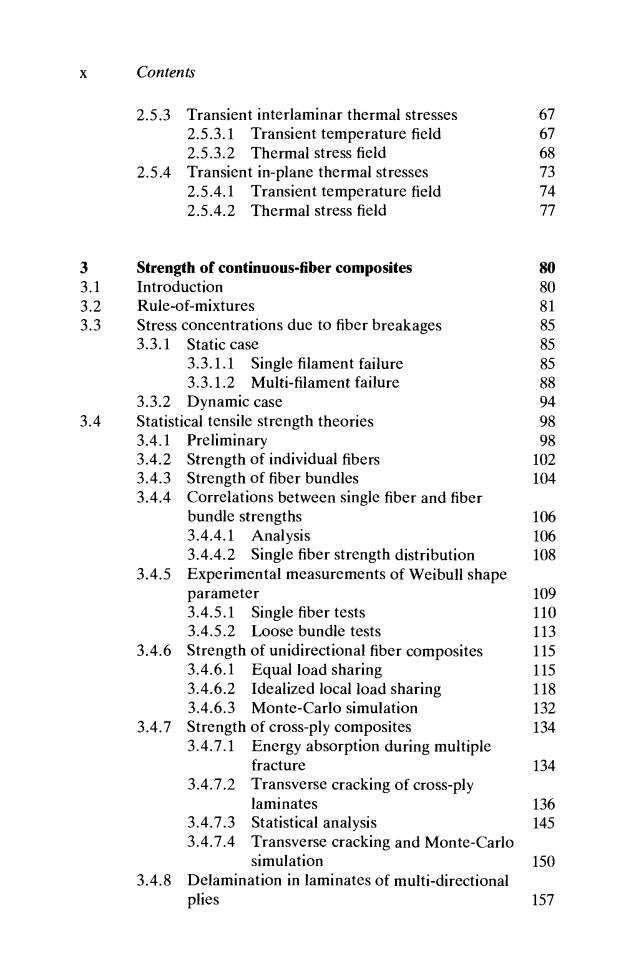

Contents 2.5.3 Transient interlaminar thermal stresses 67 2.5.3.1 Transient temperature field 67 2.5.3.2 Thermal stress field 68 2.5.4 Transient in-plane thermal stresses 73 2.5.4.1 Transient temperature field 74 2.5.4.2 Thermal stress field 77 Strength of continuous-fiber composites 80 3.1 Introduction 80 3.2 Rule-of-mixtures 81 3.3 Stress concentrations due to fiber breakages 85 3.3.1 Static case 3.3.1.1 Single filament failure 5 3.3.1.2 Multi-filament failure 3.3.2 Dynamic case 94 3.4 Statistical tensile strength theories 98 3.4.1 Preliminary 98 3.4.2 Strength of individual fibers 102 3.4.3 Strength of fiber bundles 104 3.4.4 Correlations between single fiber and fiber bundle strengths 106 3.4.4.1 Analysis 106 3.4.4.2 Single fiber strength distribution 108 3.4.5 Experimental measurements of Weibull shape parameter 109 3.4.5.1 Single fiber tests 110 3.4.5.2 Loose bundle tests 113 3.4.6 Strength of unidirectional fiber composites 115 3.4.6.1 Equal load sharing 115 3.4.6.2 Idealized local load sharing 118 3.4.6.3 Monte-Carlo simulation 132 3.4.7 Strength of cross-ply composites 134 3.4.7.1 Energy absorption during multiple fracture 134 3.4.7.2 Transverse cracking of cross-ply laminates 136 3.4.7.3 Statistical analysis 145 3.4.7.4 Transverse cracking and Monte-Carlo simulation 150 3.4.8 Delamination in laminates of multi-directional plies 157

Contents 2.5.3 Transient interlaminar thermal stresses 67 2.5.3.1 Transient temperature field 67 2.5.3.2 Thermal stress field 68 2.5.4 Transient in-plane thermal stresses 73 2.5.4.1 Transient temperature field 74 2.5.4.2 Thermal stress field 77 3 Strength of continuous-fiber composites 80 3.1 Introduction 80 3.2 Rule-of-mixtures 81 3.3 Stress concentrations due to fiber breakages 85 3.3.1 Static case 85 3.3.1.1 Single filament failure 85 3.3.1.2 Multi-filament failure 88 3.3.2 Dynamic case 94 3.4 Statistical tensile strength theories 98 3.4.1 Preliminary 98 3.4.2 Strength of individual fibers 102 3.4.3 Strength of fiber bundles 104 3.4.4 Correlations between single fiber and fiber bundle strengths 106 3.4.4.1 Analysis 106 3.4.4.2 Single fiber strength distribution 108 3.4.5 Experimental measurements of Weibull shape parameter 109 3.4.5.1 Single fiber tests 110 3.4.5.2 Loose bundle tests 113 3.4.6 Strength of unidirectional fiber composites 115 3.4.6.1 Equal load sharing 115 3.4.6.2 Idealized local load sharing 118 3.4.6.3 Monte-Carlo simulation 132 3.4.7 Strength of cross-ply composites 134 3.4.7.1 Energy absorption during multiple fracture 134 3.4.7.2 Transverse cracking of cross-ply laminates 136 3.4.7.3 Statistical analysis 145 3.4.7.4 Transverse cracking and Monte-Carlo simulation 150 3.4.8 Delamination in laminates of multi-directional plies 157

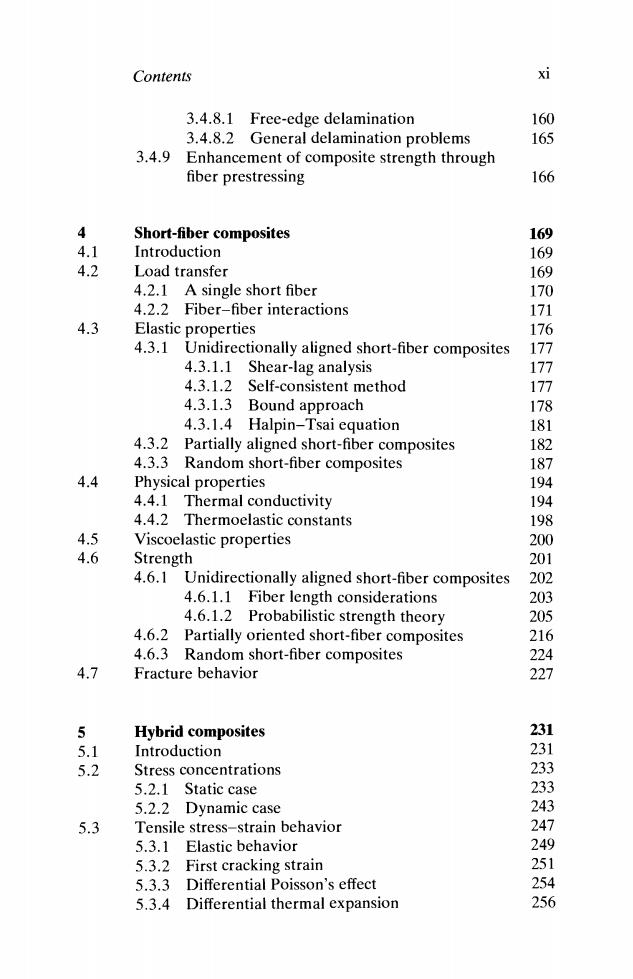

Contents 3.4.8.1 Free-edge delamination 160 3.4.8.2 General delamination problems 165 3.4.9 Enhancement of composite strength through fiber prestressing 166 4 Short-fiber composites 169 4.1 Introduction 169 4.2 Load transfer 169 4.2.1 A single short fiber 170 4.2.2 Fiber-fiber interactions 171 4.3 Elastic properties 176 4.3.1 Unidirectionally aligned short-fiber composites 177 4.3.1.1 Shear-lag analysis 177 4.3.1.2 Self-consistent method 177 4.3.1.3 Bound approach 178 4.3.1.4 Halpin-Tsai equation 181 4.3.2 Partially aligned short-fiber composites 182 4.3.3 Random short-fiber composites 187 4.4 Physical properties 194 4.4.1 Thermal conductivity 194 4.4.2 Thermoelastic constants 198 4.5 Viscoelastic properties 200 4.6 Strength 201 4.6.1 Unidirectionally aligned short-fiber composites 202 4.6.1.1 Fiber length considerations 203 4.6.1.2 Probabilistic strength theory 205 4.6.2 Partially oriented short-fiber composites 216 4.6.3 Random short-fiber composites 224 4.7 Fracture behavior 227 5 Hybrid composites 231 5.1 Introduction 231 5.2 Stress concentrations 233 5.2.1 Static case 233 5.2.2 Dynamic case 243 5.3 Tensile stress-strain behavior 247 5.3.1 Elastic behavior 249 5.3.2 First cracking strain 251 5.3.3 Differential Poisson's effect 254 5.3.4 Differential thermal expansion 256

Contents X1 3.4.8.1 Free-edge delamination 160 3.4.8.2 General delamination problems 165 3.4.9 Enhancement of composite strength through fiber prestressing 166 4 Short-fiber composites 169 4.1 Introduction 169 4.2 Load transfer 169 4.2.1 A single short fiber 170 4.2.2 Fiber-fiber interactions 171 4.3 Elastic properties 176 4.3.1 Unidirectionally aligned short-fiber composites 177 4.3.1.1 Shear-lag analysis 177 4.3.1.2 Self-consistent method 177 4.3.1.3 Bound approach 178 4.3.1.4 Halpin-Tsai equation 181 4.3.2 Partially aligned short-fiber composites 182 4.3.3 Random short-fiber composites 187 4.4 Physical properties 194 4.4.1 Thermal conductivity 194 4.4.2 Thermoelastic constants 198 4.5 Viscoelastic properties 200 4.6 Strength 201 4.6.1 Unidirectionally aligned short-fiber composites 202 4.6.1.1 Fiber length considerations 203 4.6.1.2 Probabilistic strength theory 205 4.6.2 Partially oriented short-fiber composites 216 4.6.3 Random short-fiber composites 224 4.7 Fracture behavior 227 5 Hybrid composites 231 5.1 Introduction 231 5.2 Stress concentrations 233 5.2.1 Static case 233 5.2.2 Dynamic case 243 5.3 Tensile stress-strain behavior 247 5.3.1 Elastic behavior 249 5.3.2 First cracking strain 251 5.3.3 Differential Poisson's effect 254 5.3.4 Differential thermal expansion 256