MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites CHAPTER 4 CARBON FIBER COMPOSITES 4.1 INTRODUCTION 4.2 CARBON-EPOXY COMPOSITES 4.2.1 T-500 12k/976 unidirectional tape Material Description: Material: T-50012k/976 Form: Unidirectional tape,fiber areal weight of 142 g/m,typical cured resin content of 28-34%, typical cured ply thickness of 0.0053 inches. Processing: Autoclave cure;240F,85 psi,1 hour;350F,100 psi for 2 hours. General Supplier Information: Fiber: T-500 fibers are continuous carbon filaments made from PAN precursor,surface treated to improve handling characteristics and structural properties.Filament count is 12,000 filaments/tow.Typical tensile modulus is 35.5 x 10 psi.Typical tensile strength is 575.000psi. Matrix: 976 is a high flow,modified epoxy resin that meets the NASA outgassing requirements. 10 days out-time at 72F. Maximum Short Term Service Temperature: 350°F(dry),250°F(wet) Typical applications:General purpose commercial and military structural applications,good hot/wet properties. 4-1

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-1 CHAPTER 4 CARBON FIBER COMPOSITES 4.1 INTRODUCTION 4.2 CARBON - EPOXY COMPOSITES 4.2.1 T-500 12k/976 unidirectional tape Material Description: Material: T-500 12k/976 Form: Unidirectional tape, fiber areal weight of 142 g/m2 , typical cured resin content of 28-34%, typical cured ply thickness of 0.0053 inches. Processing: Autoclave cure; 240°F, 85 psi, 1 hour; 350°F, 100 psi for 2 hours. General Supplier Information: Fiber: T-500 fibers are continuous carbon filaments made from PAN precursor, surface treated to improve handling characteristics and structural properties. Filament count is 12,000 filaments/tow. Typical tensile modulus is 35.5 x 106 psi. Typical tensile strength is 575,000 psi. Matrix: 976 is a high flow, modified epoxy resin that meets the NASA outgassing requirements. 10 days out-time at 72°F. Maximum Short Term Service Temperature: 350°F (dry), 250°F (wet) Typical applications: General purpose commercial and military structural applications, good hot/wet properties

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites 4.2.1 T500 12k/976 unidirectional tape* C/Ep 145-UT MATERIAL: T-500 12k/976 unidirectional tape T-500/976 Summary FORM: Fiberite Hy-E 3076P unidirectional tape prepreg FIBER: Union Carbide Thornel T-500 12k MATRIX: Fiberite 976 Tg(dry): 361℉ Tg(wet): Ta METHOD: PROCESSING:240F,1 hour,85 psi;350F,2 hours,100 psi DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Date of fiber manufacture Date of testing Date of resin manufacture Date of data submittal 6/88 Date of form manufacture 12/83 Date of analysis 1/93 Date of composite manufacture LAMINA PROPERTY SUMMARY 75F1A -65F1A 250F1A Tension,1-axis II-I II-I II-I Tension.2-axis II-I II-I II-I Tension,3-axis Compression,1-axis Compression,2-axis Compression,3-axis Shear,12-plane Shear,23-plane Shear.31-plane Classes of data in Strength/Modulus/Poisson's Ratio/Strain-to-Failure order:A=A75,a =A55,B B30.b B18. M=Mean,I Interim,s=Screening,-=no data (See Table 1.4.2(c)) 4-2

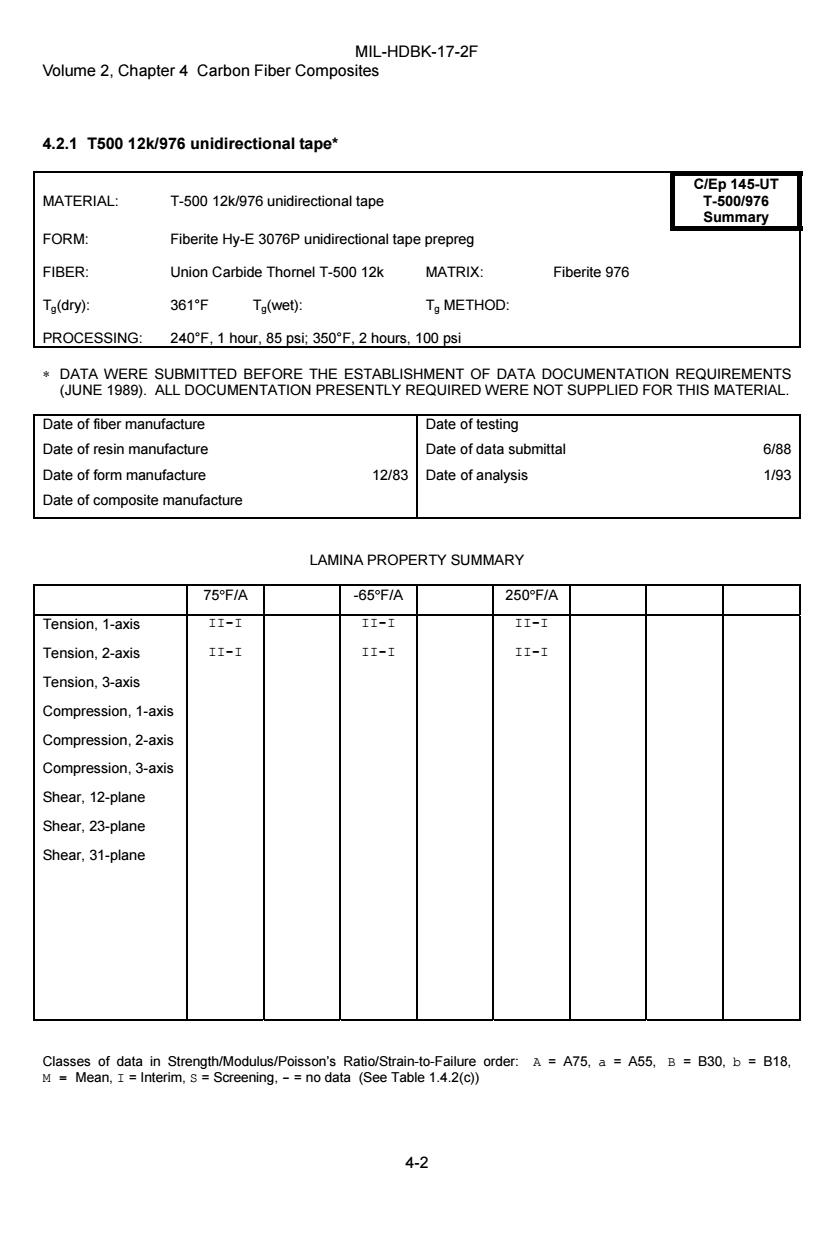

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-2 4.2.1 T500 12k/976 unidirectional tape* C/Ep 145-UT MATERIAL: T-500 12k/976 unidirectional tape T-500/976 Summary FORM: Fiberite Hy-E 3076P unidirectional tape prepreg FIBER: Union Carbide Thornel T-500 12k MATRIX: Fiberite 976 Tg(dry): 361°F Tg(wet): Tg METHOD: PROCESSING: 240°F, 1 hour, 85 psi; 350°F, 2 hours, 100 psi ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Date of fiber manufacture Date of testing Date of resin manufacture Date of data submittal 6/88 Date of form manufacture 12/83 Date of analysis 1/93 Date of composite manufacture LAMINA PROPERTY SUMMARY 75°F/A -65°F/A 250°F/A Tension, 1-axis II-I II-I II-I Tension, 2-axis II-I II-I II-I Tension, 3-axis Compression, 1-axis Compression, 2-axis Compression, 3-axis Shear, 12-plane Shear, 23-plane Shear, 31-plane Classes of data in Strength/Modulus/Poisson’s Ratio/Strain-to-Failure order: A = A75, a = A55, B = B30, b = B18, M = Mean, I = Interim, S = Screening, - = no data (See Table 1.4.2(c))

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Nominal As Submitted Test Method Fiber Density (g/cm) 1.79 Resin Density (g/cm) 1.28 Composite Density (g/cm3) 1.59 1.57.1.61 Fiber Areal Weight (g1m3) 142 142-146 Fiber Volume (%) Ply Thickness (in) 0.0053 0.0050-0.0057 LAMINATE PROPERTY SUMMARY Classes of data in Strength/Modulus/Poisson's Ratio/Strain-to-Failure order:A A75,a =A55,B=B30,b B18, M Mean,I Interim,s Screening,-=no data (See Table 1.4.2(c)) 4-3

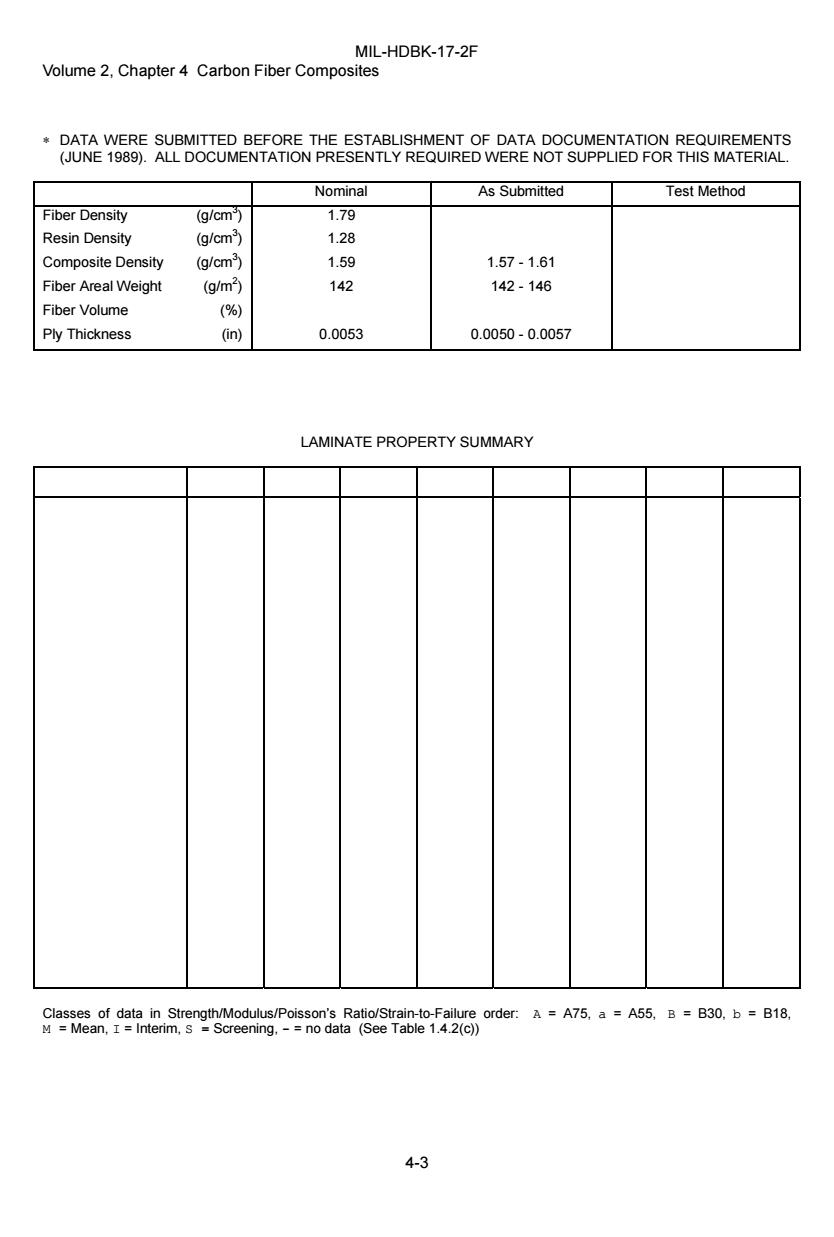

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-3 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Nominal As Submitted Test Method Fiber Density (g/cm3 ) 1.79 Resin Density (g/cm3 ) 1.28 Composite Density (g/cm3 ) 1.59 1.57 - 1.61 Fiber Areal Weight (g/m2 ) 142 142 - 146 Fiber Volume (%) Ply Thickness (in) 0.0053 0.0050 - 0.0057 LAMINATE PROPERTY SUMMARY Classes of data in Strength/Modulus/Poisson’s Ratio/Strain-to-Failure order: A = A75, a = A55, B = B30, b = B18, M = Mean, I = Interim, S = Screening, - = no data (See Table 1.4.2(c))

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: T-500 12k/976 unidirectional tape Table 4.2.1(a) C/Ep 142-UT RESIN CONTENT: 28-34wt% COMP:DENSITY: 1.57-1.61g/cm3 T-500/976 FIBER VOLUME: 59-64% VOID CONTENT: 0.3-1.7% Tension,1-axis PLY THICKNESS: 0.0050-0.0057in. [01g 75/A.-65/A,2001A TEST METHOD: MODULUS CALCULATION: Interim ASTM D 3039-76 Chord,20-40%of ultimate load NORMALIZED BY: Specimen thickness and batch fiber volume to 60%fiber volume(0.0052 in.CPT) Temperature (F) 75 -65 250 Moisture Content(%)】 ambient ambient ambient Equilibrium at T.RH Source Code 13 13 13 Normalized Measured Normalized Measured Normalized Measured Mean 295 298 213 213 273 276 Minimum 257 270 163 196 236 258 Maximum 329 328 243 235 302 310 c.V.(%) 6.41 5.74 9.78 5.02 7.39 6.05 B-value (1) (1) (1) Fu Distribution ANOVA Weibull Weibull (ksi) C1 20.5 221 282 C2 4.64 13.1 15.7 No.Specimens 15 15 No.Batches 3 3 3 Data Class Interim Interim Interim Mean 21.9 22.0 19.0 19.1 22.2 22.4 Minimum 20.9 20.5 15.9 17.7 18.6 21.0 Maximum 24.7 24.0 21.5 21.5 25.1 23.8 E时 C.V.(%) 4.42 4.15 8.11 5.76 6.91 4.17 (Msi) No.Specimens 15 15 15 No.Batches 3 3 Data Class Interim Interim Interim Mean No.Specimens 啦 No.Batches Data Class Mean 13000 10700 11800 Minimum 11700 9300 10800 Maximum 13900 12000 12900 C.V.(%) 4.98 5.98 5.32 B-value (1) (1) (1) e” Distribution ANOVA Weibull Weibull (LE) C1 706 11000 12100 C2 4.75 18.8 21.6 No.Specimens 15 15 15 No.Batches 3 3 3 Data Class Interim Interim Interim (1) Basis values are presented only for A and B data classes. 4-4

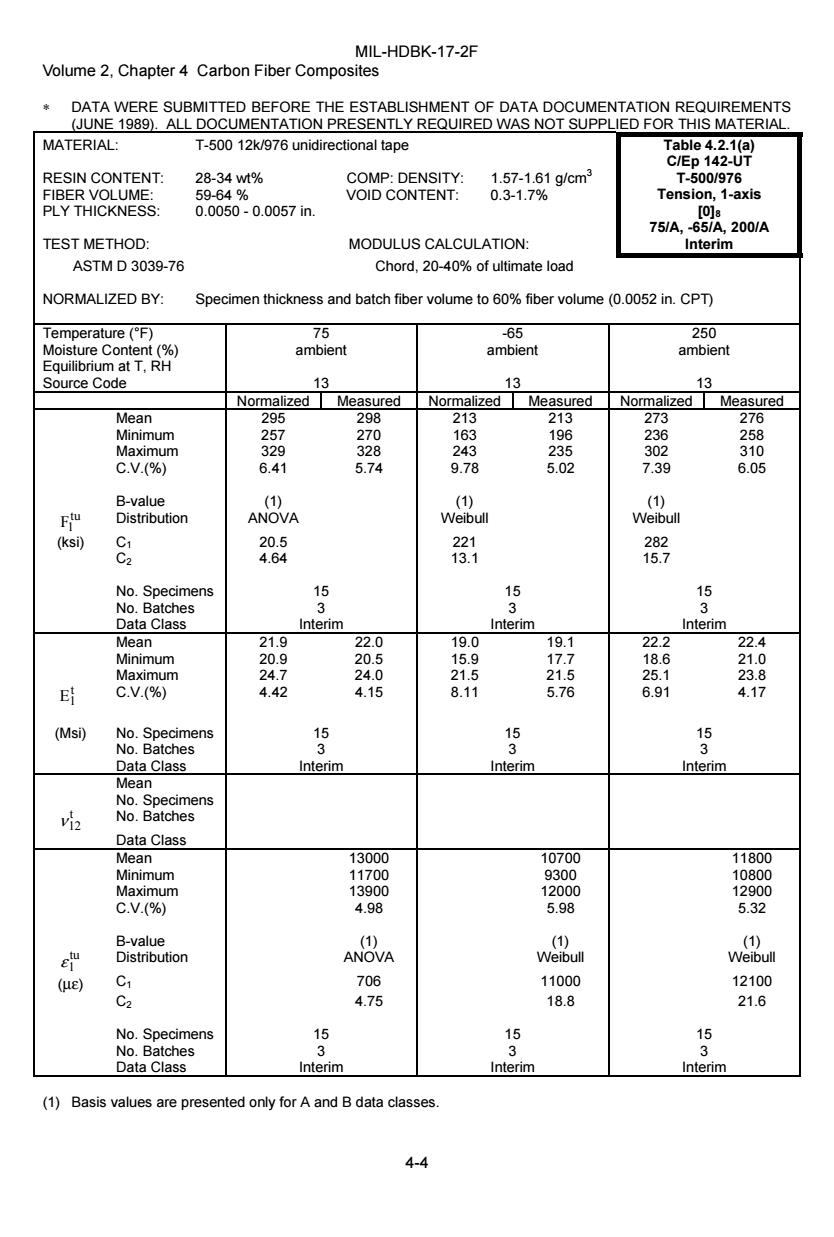

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-4 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: T-500 12k/976 unidirectional tape Table 4.2.1(a) C/Ep 142-UT RESIN CONTENT: 28-34 wt% COMP: DENSITY: 1.57-1.61 g/cm3 T-500/976 FIBER VOLUME: 59-64 % VOID CONTENT: 0.3-1.7% Tension, 1-axis PLY THICKNESS: 0.0050 - 0.0057 in. [0]8 75/A, -65/A, 200/A TEST METHOD: MODULUS CALCULATION: Interim ASTM D 3039-76 Chord, 20-40% of ultimate load NORMALIZED BY: Specimen thickness and batch fiber volume to 60% fiber volume (0.0052 in. CPT) Temperature (°F) 75 -65 250 Moisture Content (%) ambient ambient ambient Equilibrium at T, RH Source Code 13 13 13 Normalized Measured Normalized Measured Normalized Measured Mean 295 298 213 213 273 276 Minimum 257 270 163 196 236 258 Maximum 329 328 243 235 302 310 C.V.(%) 6.41 5.74 9.78 5.02 7.39 6.05 B-value (1) (1) (1) Ftu 1 Distribution ANOVA Weibull Weibull (ksi) C1 20.5 221 282 C2 4.64 13.1 15.7 No. Specimens 15 15 15 No. Batches 3 3 3 Data Class Interim Interim Interim Mean 21.9 22.0 19.0 19.1 22.2 22.4 Minimum 20.9 20.5 15.9 17.7 18.6 21.0 Maximum 24.7 24.0 21.5 21.5 25.1 23.8 Et 1 C.V.(%) 4.42 4.15 8.11 5.76 6.91 4.17 (Msi) No. Specimens 15 15 15 No. Batches 3 3 3 Data Class Interim Interim Interim Mean No. Specimens ν 12 t No. Batches Data Class Mean 13000 10700 11800 Minimum 11700 9300 10800 Maximum 13900 12000 12900 C.V.(%) 4.98 5.98 5.32 B-value (1) (1) (1) ε 1 tu Distribution ANOVA Weibull Weibull (µε) C1 706 11000 12100 C2 4.75 18.8 21.6 No. Specimens 15 15 15 No. Batches 3 3 3 Data Class Interim Interim Interim (1) Basis values are presented only for A and B data classes

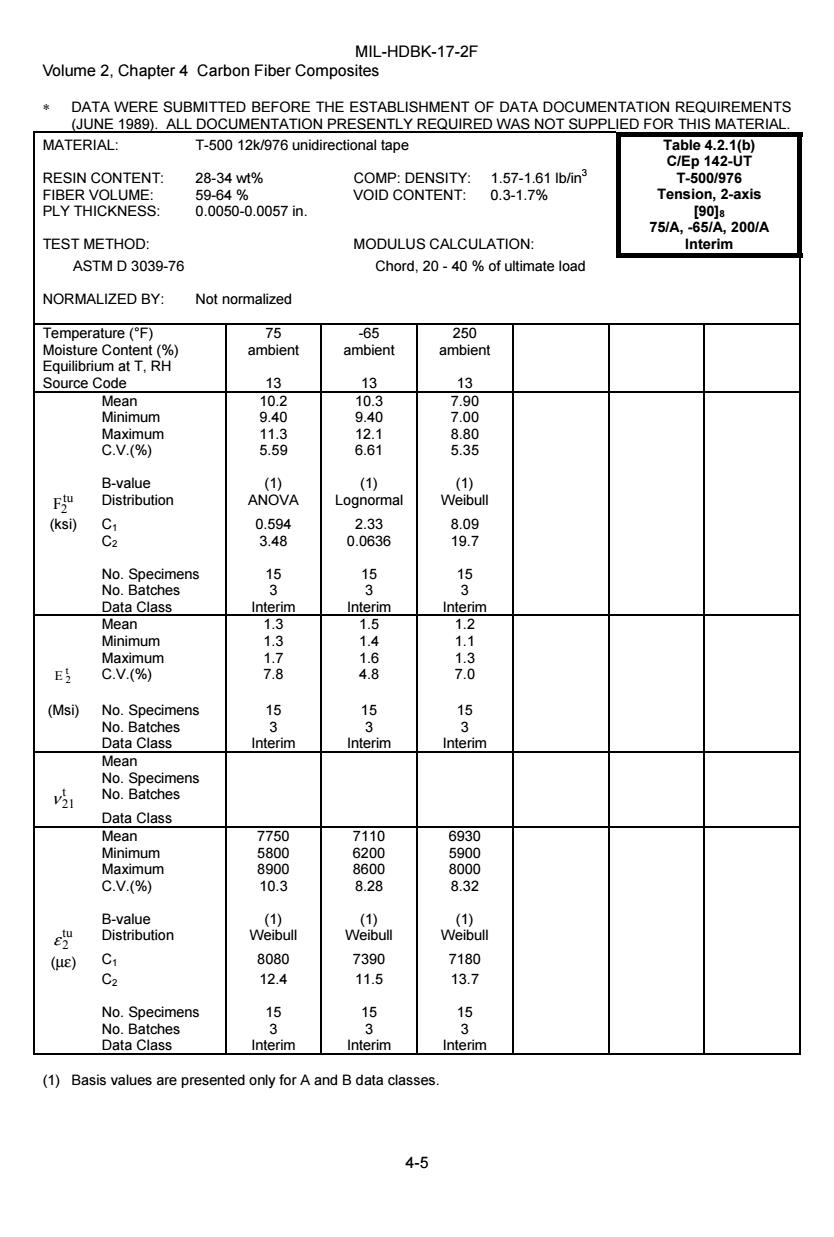

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL MATERIAL: T-500 12k/976 unidirectional tape Table 4.2.1(b) C/Ep 142-UT RESIN CONTENT: 28-34wt% COMP:DENSITY:1.57-1.61 lb/in3 T-500/976 FIBER VOLUME: 59-64% VOID CONTENT:0.3-1.7% Tension,2-axis PLY THICKNESS: 0.0050-0.0057in. [90]8 75/A,-65/A,2001A TEST METHOD: MODULUS CALCULATION: Interim ASTMD 3039-76 Chord,20-40 of ultimate load NORMALIZED BY: Not normalized Temperature (F) 75 -65 250 Moisture Content(%)】 ambient ambient ambient Equilibrium at T.RH Source Code 13 13 13 Mean 10.2 10.3 7.90 Minimum 9.40 9.40 7.00 Maximum 11.3 12.1 8.80 C.V.(%) 5.59 6.61 5.35 B-value (1) (1) (1) F Distribution ANOVA Lognormal Weibull (ksi) C1 0.594 2.33 8.09 C2 3.48 0.0636 19.7 No.Specimens 15 15 15 No.Batches 0 3 Data Class Interim Interim Interim Mean 1.3 1.5 1.2 Minimum 1.3 1.4 1.1 Maximum 1.7 1.6 1.3 ES C.V.(%) 7.8 4.8 7.0 (Msi) No.Specimens 15 15 15 No.Batches 3 3 3 Data Class Interim Interim Interim Mean No.Specimens v21 No.Batches Data Class Mean 7750 7110 6930 Minimum 5800 6200 5900 Maximum 8900 8600 8000 C.V.(%) 10.3 8.28 8.32 B-value (1) (1) (1) 咒 Distribution Weibull Weibull Weibull (uE) C1 8080 7390 7180 C2 12.4 11.5 13.7 No.Specimens 15 15 15 No.Batches 3 3 3 Data Class Interim Interim Interim (1) Basis values are presented only for A and B data classes. 4-5

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-5 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: T-500 12k/976 unidirectional tape Table 4.2.1(b) C/Ep 142-UT RESIN CONTENT: 28-34 wt% COMP: DENSITY: 1.57-1.61 lb/in3 T-500/976 FIBER VOLUME: 59-64 % VOID CONTENT: 0.3-1.7% Tension, 2-axis PLY THICKNESS: 0.0050-0.0057 in. [90]8 75/A, -65/A, 200/A TEST METHOD: MODULUS CALCULATION: Interim ASTM D 3039-76 Chord, 20 - 40 % of ultimate load NORMALIZED BY: Not normalized Temperature (°F) 75 -65 250 Moisture Content (%) ambient ambient ambient Equilibrium at T, RH Source Code 13 13 13 Mean 10.2 10.3 7.90 Minimum 9.40 9.40 7.00 Maximum 11.3 12.1 8.80 C.V.(%) 5.59 6.61 5.35 B-value (1) (1) (1) Ftu 2 Distribution ANOVA Lognormal Weibull (ksi) C1 0.594 2.33 8.09 C2 3.48 0.0636 19.7 No. Specimens 15 15 15 No. Batches 3 3 3 Data Class Interim Interim Interim Mean 1.3 1.5 1.2 Minimum 1.3 1.4 1.1 Maximum 1.7 1.6 1.3 E t 2 C.V.(%) 7.8 4.8 7.0 (Msi) No. Specimens 15 15 15 No. Batches 3 3 3 Data Class Interim Interim Interim Mean No. Specimens ν 21 t No. Batches Data Class Mean 7750 7110 6930 Minimum 5800 6200 5900 Maximum 8900 8600 8000 C.V.(%) 10.3 8.28 8.32 B-value (1) (1) (1) ε 2 tu Distribution Weibull Weibull Weibull (µε) C1 8080 7390 7180 C2 12.4 11.5 13.7 No. Specimens 15 15 15 No. Batches 3 3 3 Data Class Interim Interim Interim (1) Basis values are presented only for A and B data classes