•基本工作原理 马米藏江

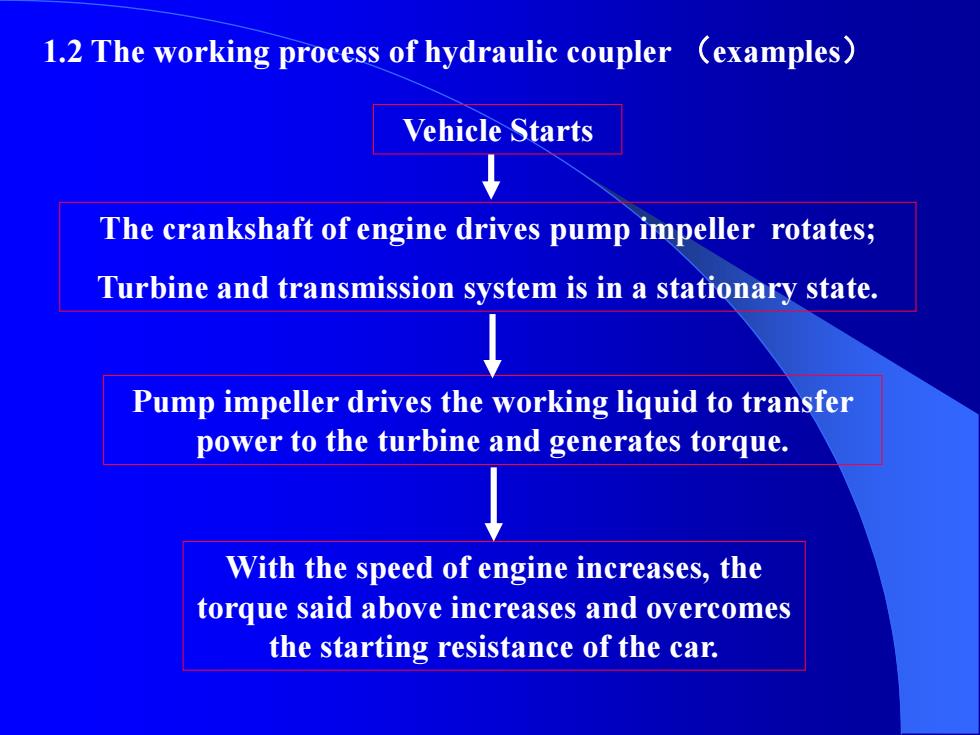

1.2 The working process of hydraulic coupler (examples) Vehicle Starts The crankshaft of engine drives pump impeller rotates; Turbine and transmission system is in a stationary state. Pump impeller drives the working liquid to transfer power to the turbine and generates torque. With the speed of engine increases,the torque said above increases and overcomes the starting resistance of the car

1.2 The working process of hydraulic coupler (examples) Vehicle Starts The crankshaft of engine drives pump impeller rotates; Turbine and transmission system is in a stationary state. Pump impeller drives the working liquid to transfer power to the turbine and generates torque. With the speed of engine increases, the torque said above increases and overcomes the starting resistance of the car

The advantages and disadvantages of a car using hydraulic coupler Advantages: >A greater speed difference between pump impeller and turbine is allowed It can ensure a smooth a start-up and acceleration of the car.And it can attenuate the overload caused by torsional vibration at the same time. >N The application of it is gradually ift gea reduced nowadays. DIsadvantages: >Hydraulic coupler can only transfer torque but can't change torque. Therefore it must be used together with speed-change mechanism. >The quality and size increase.Because the hydraulic coupler can't totally cut off power.In order to reduce the impact at shifting gears,a clutch is still needed to interrupt power. >Existing fluid flow loss,so the efficiency of transmission is low

The advantages and disadvantages of a car using hydraulic coupler Advantages: A greater speed difference between pump impeller and turbine is allowed . It can ensure a smooth a start-up and acceleration of the car. And it can attenuate the overload caused by torsional vibration at the same time. Prolong the service life of the drive system; Needn’t cut of the drive system at the temporary parking, so we can shift gears less frequently. Disadvantages: Hydraulic coupler can only transfer torque but can’t change torque. Therefore it must be used together with speed-change mechanism. The quality and size increase. Because the hydraulic coupler can't totally cut off power. In order to reduce the impact at shifting gears, a clutch is still needed to interrupt power. Existing fluid flow loss, so the efficiency of transmission is low. The application of it is gradually reduced nowadays

2 Hydrodynamic torque converter 液力变矩器的结构与 工作原理 1.结构 1-变矩 器壳 2-涡轮 3-导轮 4泵轮

2、 Hydrodynamic torque converter

工作原理 8