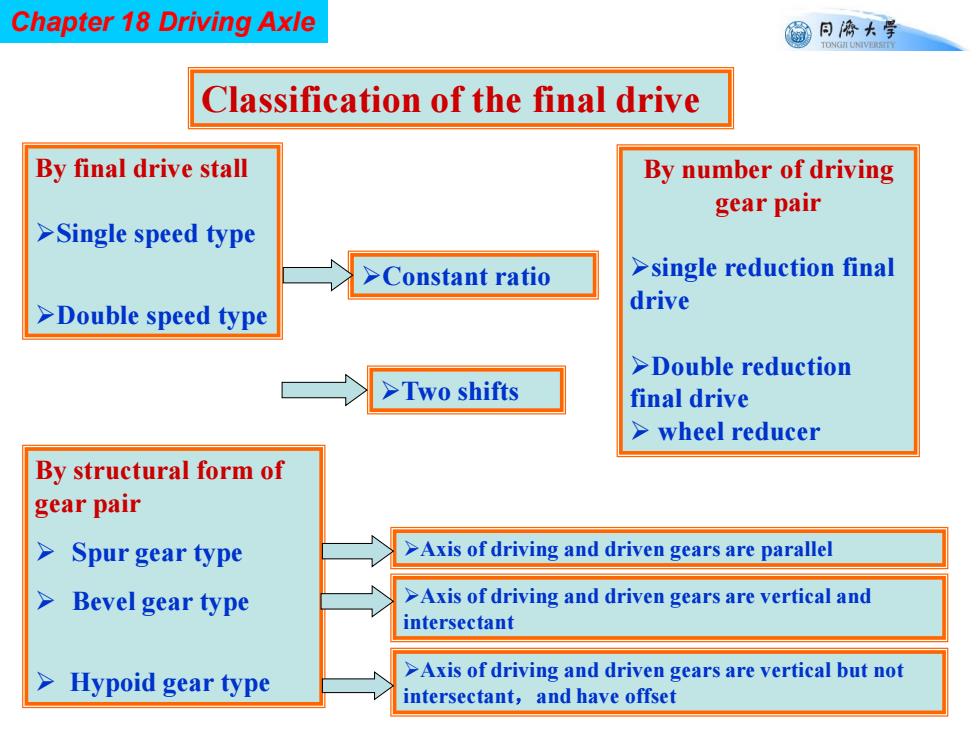

Chapter 18 Driving Axle 月儕大学 TONGII UNIVERSTTY Classification of the final drive By final drive stall By number of driving gear pair >Single speed type Constant ratio >single reduction final >Double speed type drive >Double reduction >Two shifts final drive wheel reducer By structural form of gear pair Spur gear type >Axis of driving and driven gears are parallel Bevel gear type >Axis of driving and driven gears are vertical and intersectant >Hypoid gear type >Axis of driving and driven gears are vertical but not intersectant,and have offset

Chapter 18 Driving Axle By number of driving gear pair single reduction final drive Double reduction final drive wheel reducer Classification of the final drive By final drive stall Single speed type Double speed type By structural form of gear pair Spur gear type Bevel gear type Hypoid gear type Constant ratio Two shifts Axis of driving and driven gears are parallel Axis of driving and driven gears are vertical and intersectant Axis of driving and driven gears are vertical but not intersectant,and have offset

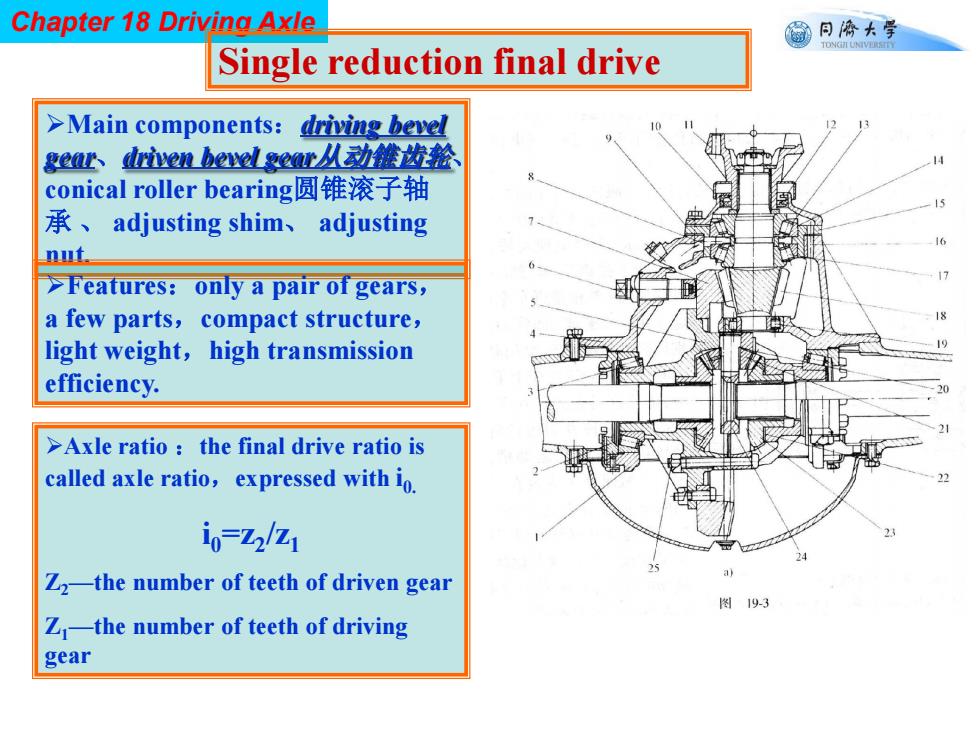

Chapter 18 Drivina Axle 同©大学 TONGII UNIVERSTTY Single reduction final drive >Main components:driving bevel &ear driven bevelgear从动能齿羞 conical roller bearing圆锥滚子轴 承、adjusting shim、:adjusting nuf. 17 >Features:only a pair of gears, a few parts,compact structure, 18 light weight,high transmission 19 efficiency. 20 >Axle ratio the final drive ratio is called axle ratio,expressed with io. 22 i0=Z2l21 Z2-the number of teeth of driven gear a) 图19-3 Z-the number of teeth of driving gear

Chapter 18 Driving Axle Single reduction final drive Main components:driving bevel gear、driven bevel gear从动锥齿轮、 conical roller bearing圆锥滚子轴 承 、 adjusting shim、 adjusting nut. Axle ratio :the final drive ratio is called axle ratio,expressed with i0. i0=z2 /z1 Z2—the number of teeth of driven gear Z1—the number of teeth of driving gear Features:only a pair of gears, a few parts,compact structure, light weight,high transmission efficiency

Chapter 18 Driving Axle 日儕大学 TONGII UNIVERSITY Single reduction final drive >Correct meshing position between driving and driven bevel gear >Try to reduce noise during the meshing >Necessary of driving and driven gears,and enable meshing adjusting even wearing along the length device >To enable driving and driven gears to have enough bearing stiffness in structure >To avoid large deformation during transmission process,which affects normal meshing

Chapter 18 Driving Axle Single reduction final drive Correct meshing position between driving and driven bevel gear To enable driving and driven gears to have enough bearing stiffness in structure Try to reduce noise during the meshing of driving and driven gears,and enable even wearing along the length To avoid large deformation during transmission process, which affects normal meshing Necessary meshing adjusting device

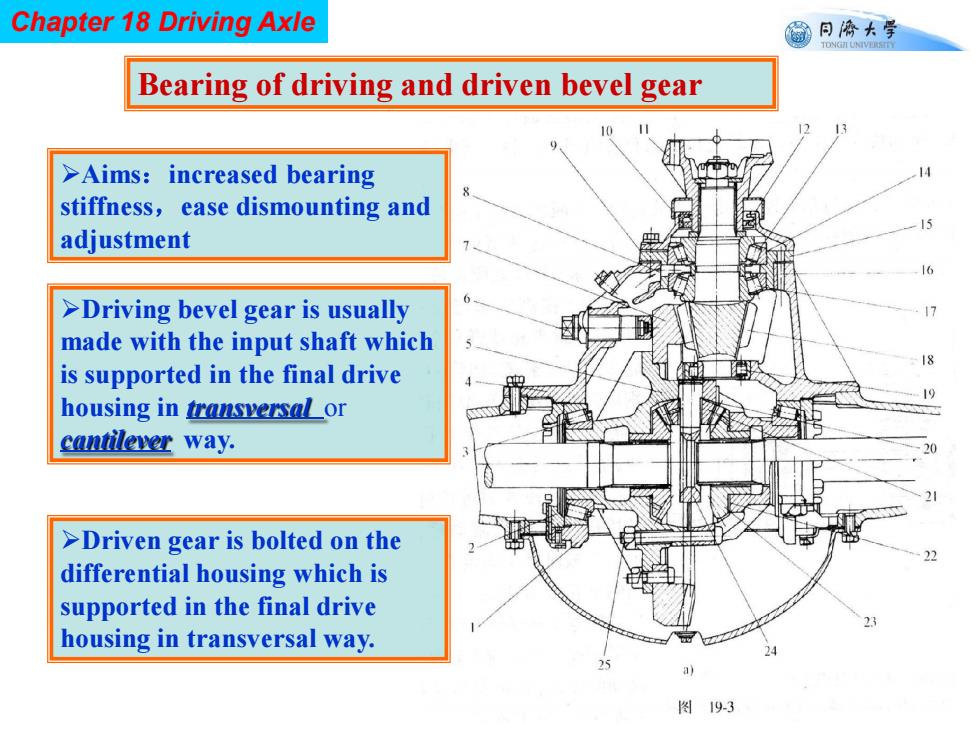

Chapter 18 Driving Axle 同©大学 TONGII UNIVERSTTY Bearing of driving and driven bevel gear 1( >Aims:increased bearing stiffness,ease dismounting and 15 adjustment 16 >Driving bevel gear is usually made with the input shaft which 18 is supported in the final drive 19 housing in transyersal or cantilever way. >Driven gear is bolted on the differential housing which is supported in the final drive 23 housing in transversal way. 2 图19-3

Chapter 18 Driving Axle Bearing of driving and driven bevel gear Aims:increased bearing stiffness,ease dismounting and adjustment Driving bevel gear is usually made with the input shaft which is supported in the final drive housing in transversal or cantilever way. Driven gear is bolted on the differential housing which is supported in the final drive housing in transversal way

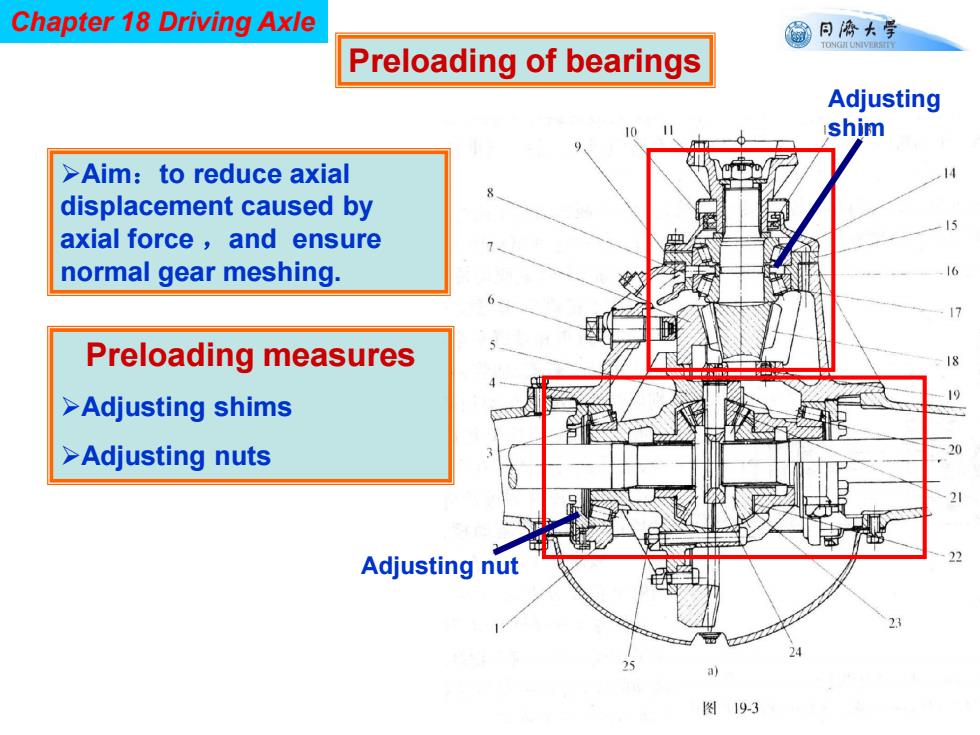

Chapter 18 Driving Axle 同©大学 TONGII UNIVERSTTY Preloading of bearings Adjusting shim >Aim:to reduce axial P displacement caused by 15 axial force and ensure normal gear meshing. 16 17 Preloading measures 19 >Adjusting shims >Adjusting nuts )0 Adjusting nut 22 图19-3

Chapter 18 Driving Axle Preloading of bearings Aim:to reduce axial displacement caused by axial force ,and ensure normal gear meshing. Preloading measures Adjusting shims Adjusting nuts Adjusting nut Adjusting shim